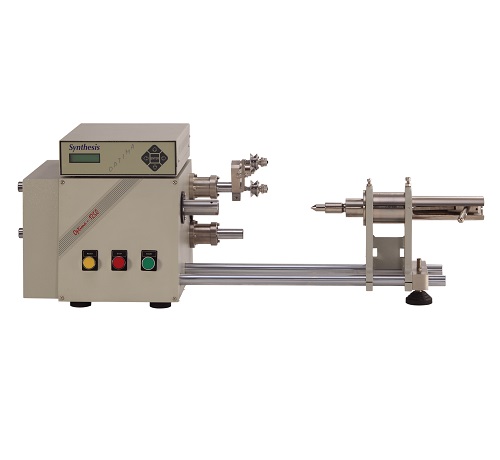

Layer Winding Machine

A layer winding machine is a specialized device used in the manufacturing of coils and inductors with precise layering. These machines automate the process of winding wire around a core in concentric layers, ensuring uniform distribution and optimal performance of the final electromagnetic components. Layer winding machines play a crucial role in industries such as electronics, telecommunications, power generation, and automotive, where coils with accurate layering are essential for efficient operation.

Features of Layer Winding Machines:

Automated Layering : Layer winding machines automate the process of winding wire around the core in concentric layers, ensuring consistent and precise winding.

Variable Speed Control : These machines offer variable speed controls to adapt to different wire types, gauges, and layering requirements.

Tension Control : Tension control mechanisms maintain optimal wire tension during the winding process, preventing wire slack or breakage.

Wire Guide Systems : Advanced wire guide systems position the wire accurately on the core, reducing the risk of overlapping or misplacement.

Programmable Parameters : Many machines allow users to program layering parameters, including wire diameter, turns count per layer, and overall layer count.

Customizable Core Compatibility : These layer winding machines can accommodate various core shapes and sizes, enhancing versatility in component manufacturing.

Counters and Sensors : Layer winding machines feature counters and sensors that track the number of windings per layer, ensuring accuracy.

Benefits of Layer Winding Machines:

Precise Layering: Layer winding machines ensure accurate and consistent layering of wire, resulting in high-quality coils and inductors.

Time Efficiency : Automation speeds up the layering process, enhancing overall production efficiency and reducing manufacturing time.

Material Utilization : Accurate layering reduces material waste and optimizes resource utilization.

Enhanced Quality Control : These machines minimize the risk of human errors, resulting in higher product quality and reduced defect rates.

Applications of Layer Winding Machines:

Inductors : Layer winding machines are essential for producing inductors used in various electronic devices, power supplies, and communication systems.

Transformers : Transformers, used in power distribution and voltage conversion, require precise layering for optimal performance.

Coils : Coils used in electromechanical devices such as motors, solenoids, and generators benefit from the consistent layering provided by these machines.

Magnetic Field Assistance:

Magnetic coilers utilize magnetic fields to guide and facilitate the winding of wire around the core, ensuring uniform and controlled winding.

Variable Speed Control:

These machines offer variable speed controls to adapt to different wire types, gauges, and winding requirements.

Tension Control:

Advanced tension control mechanisms maintain optimal wire tension during the winding process, preventing wire slack or breakage.

Wire Guide Systems:

Magnetic coilers are equipped with precise wire guide systems that help position the wire accurately on the core, minimizing the risk of overlapping or misplacement.

Programmable Parameters:

Many machines allow users to program winding parameters, including wire diameter, turns count, layering, and more.

Customizable Core Compatibility:

These magnetic coilers accommodate various core shapes and sizes, offering versatility in component manufacturing.

Automated Counting and Sensors:

Magnetic coilers feature counters and sensors that track the number of windings, ensuring accuracy in production.

Benefits of Magnetic Coilers:

Precision and Consistency: Magnetic coilers ensure consistent and precise winding, leading to the creation of high-quality electromagnetic components.

Time Efficiency:

Automation speeds up the winding process, enhancing overall production efficiency and reducing manufacturing time.

Optimized Resource Utilization:

Accurate winding reduces material waste, contributing to efficient resource management.

Enhanced Quality Control:

These machines minimize the risk of human errors, resulting in higher product quality and reduced defect rates.

Applications of Magnetic Coilers:

Electromagnetic Components: Magnetic coilers are used in manufacturing coils, inductors, solenoids, and other electromagnetic components for various industries.

Telecommunications:

Coils used in communication devices, antennas, and signal processing equipment benefit from the precision of magnetic coilers.

Power Generation:

Magnetic coilers are utilized in the production of inductors and coils for generators and alternators.

Automotive Industry:

Components such as ignition coils and sensors in automobiles rely on the accurate winding provided by magnetic coilers.

Conclusion:

In conclusion, layer winding machines are vital tools in the production of coils and inductors with accurate and consistent layering. By automating the layering process, these machines enhance production efficiency, product quality, and customization options. Layer winding machines contribute to the reliability and performance of a wide range of industries, from electronics to power generation, by delivering high-quality coils and inductors with optimal layering for efficient operation.