Winding Machines: The Path to Cost Reduction and Superior Quality

Introduction

In the pulse of modern manufacturing, countless revolutions are happening unnoticed. Spools spinning, wires weaving, motors and textiles coming together coil by coil. Yet behind this choreography, a subtle transformation is at work. Instead of relentless cost-cutting marathons or last-minute scrambles for quality, manufacturers are harnessing a new kind of force. They have started to implement winding machine as a strategic partner. Here, mundane repetition disappears, and every rotation becomes a statement of purpose. Here automation isn’t just a buzzword, but the architect of sharper productivity and financial clarity.

The new reality is unmistakable: it’s not just what you make, but how you make it that defines value. Winding machines are quietly rewriting the story, delivering cost reduction and unwavering quality not through luck, but as a built-in feature of advanced engineering. Step beyond the spreadsheets and into the heart of the factory: the true ROI is found wherever innovation turns, and winding machines are leading the way.

Automation: The Engine of Transformation

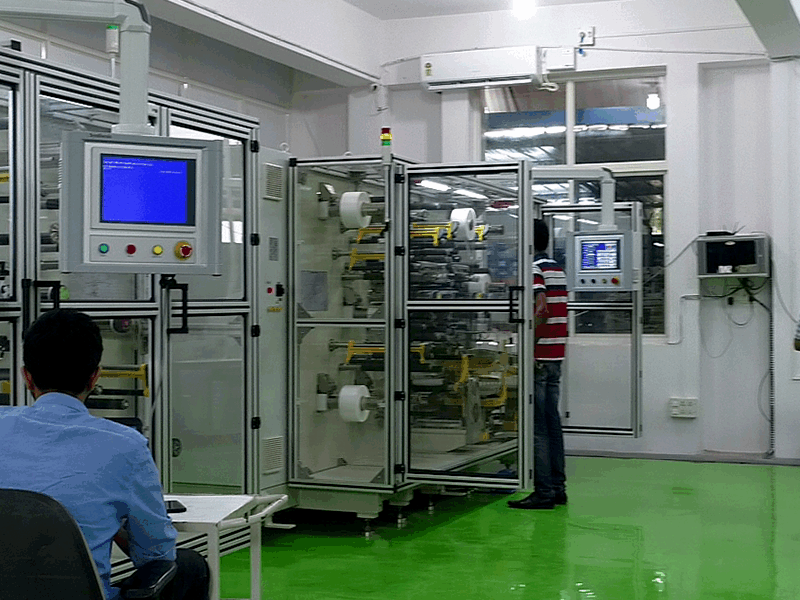

The shift from manual to automated winding has been a game changer for manufacturers across industries. With mechanized systems, time-consuming, repetitive workflows give way to streamlined cycles where high-speed spindles execute programmable routines with remarkable accuracy. Automation means that tasks once dependent on skilled labour can now be performed continuously, even overnight, ensuring production lines run with minimal interruption.

This unfailing consistency has a ripple effect across every cost centre. Automated winding machines reduce labour needs, lower the risk of human error, and allow for the reallocation of teams to more strategic functions such as quality control and process optimization. Employees can focus on value-added activities, while machines carry the burden of high-volume output. The result is higher productivity, not just measured by units produced, but by the improved allocation of human talent.

Quality: Precision Drives Results

A manufacturer’s reputation is only as strong as its weakest component. With winding tasks that demand uniform tension, geometric exactness, and material optimization, the stakes are high. Automated winding machines are engineered to deliver this precision by regulating speed, tension, and layer-by-layer placement within exacting tolerances. Advanced sensor systems and feedback controls maintain uniformity from the first coil to the ten-thousandth, dramatically improving the overall standard of output.

What does this mean for manufacturers? Fewer defects, less scrap, and reduced costs for rework or warranty claims. The ability to meet or exceed customer specifications becomes routine, rather than a lucky outcome. In industries where minute variations can affect end-product performance such as electronics, automotive, and medical devices, achieving and maintaining high quality is a source of competitive strength.

Cost Reduction: Every Revolution Counts

For many manufacturing leaders, the most attractive benefit of winding machines is their impact on the bottom line. The transition to automation slashes direct labour expenses, but the savings extend beyond payroll. Machines optimize material usage, reducing waste and ensuring that every inch of wire or textile finds its intended place. Reductions in scrap not only save on raw materials but also eliminate the cascading costs of disposal and environmental compliance.

Maintenance costs are also kept low, thanks to predictive diagnostics and self-monitoring features in modern winding machines. These systems can identify wear or misalignment before it becomes a problem, scheduling maintenance during downtimes and preventing costly breakdowns. Manufacturers can manage inventory and production schedules more accurately, anticipating both expenses and capacity.

Productivity: Unleashing Throughput

Speed without sacrificing accuracy is the hallmark of contemporary winding machines. Whether producing coils, transformers, or yarn packages, automation allows for multi-spindle setups and non-stop operation. This high-throughput capability enables manufacturers to fulfil larger orders, respond quickly to spikes in market demand, or switch between product lines with minimal downtime.

Elevated productivity means reduced cycle times and faster turnaround, both of which translate to competitive advantage. By accomplishing more within a given shift, companies can maximize revenue potential without overextending their workforce or facilities. The ability to scale production flexibly allows manufacturers to adapt to market changes quickly, harnessing full capacity when needed and dialling back without unnecessary waste.

ROI: Investing for Long-Term Gains

The upfront investment in winding machines is quickly recouped through a combination of labour savings, quality improvement, and enhanced efficiency. This will result in a robust ROI. Automated systems allow for vertical and horizontal expansion, supporting new product types and market segments without the need for extensive retraining or retooling. The flexibility to run short, custom batches as easily as mass production increases the value of every dollar spent on equipment.

As manufacturers evaluate capital expenditures, the long-term economic benefits of winding automation stack up clearly. Lower operational costs, fewer mistakes, more reliable delivery schedules, and the capacity for innovation in future processes. Companies that embrace modern winding machines consistently report shorter payback periods and ongoing savings that fuel growth and reinvestment.

The Future of Winding Machines: Continuous Evolution

As digital technologies evolve and manufacturing standards become even more exacting, the capabilities of winding machines continue to expand. Integration with factory management software, adoption of IoT-based monitoring, and real-time data analysis mean that tomorrow’s winding floors will be even smarter, more productive, and more cost-effective.

The relentless pursuit of efficiency now has proved that winding machines not only promise but deliver measurable improvements in cost reduction, quality, productivity, and ROI. Manufacturers willing to invest in automation are rewarded not just with immediate savings, but with a platform for ongoing innovation. This helps in securing their place at the forefront of today’s competitive landscape.

Conclusion

In manufacturing, the margin between profit and loss is often found in the details. Winding machines, with their blend of automation, precision, and reliability, offer a blueprint for continuous improvement. They free up human talent for higher-order tasks, safeguard quality with every cycle, and generate cost savings that compound with scale. For companies carving out their future in an ever-challenging marketplace, winding machine technology stands as both a strategic investment and a practical solution, driving better products and stronger financial returns with every revolution.