Trends in Micro-Winding Machines for Small-Scale Electronics

Introduction

The electronics industry is experiencing an unprecedented transformation driven by the relentless pursuit of miniaturization. From wearable health monitors that track vital signs to Internet of Things sensors embedded in industrial equipment, modern devices demand components that are smaller, more precise, and more reliable than ever before.

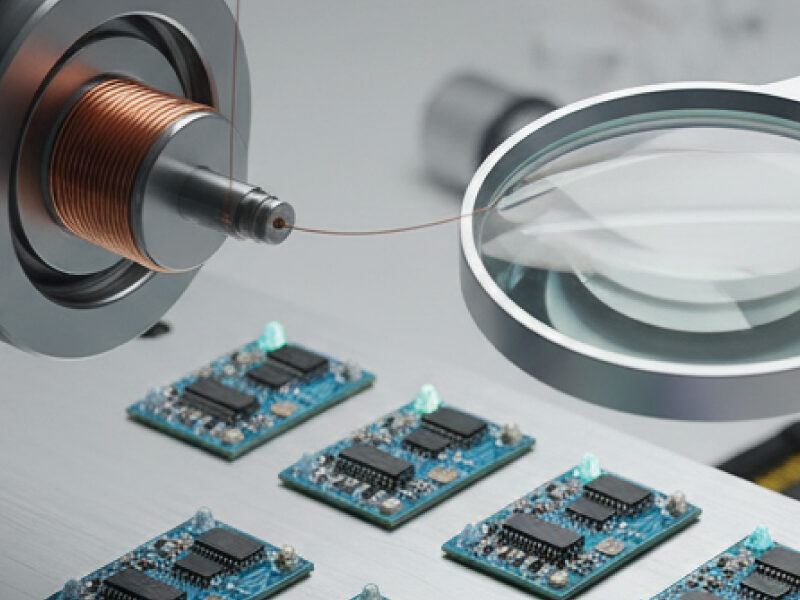

This shift has placed micro-winding technology at the forefront of manufacturing innovation, as the ability to create coils from wires thinner than a human hair has become critical for next-generation electronics.

The global coil-winding machine market, valued at approximately USD 2.2 billion in 2023, is projected to reach USD 3.8 billion by 2032, growing at a compound annual growth rate of 7.9%. This growth trajectory reflects the escalating demand for precision winding solutions capable of handling the intricate requirements of small-scale electronic components.

The Rise of Micro-Winding Technology

The surge in micro-winding capabilities stems directly from the explosive growth of compact electronic devices across multiple sectors. Consumer electronics manufacturers are packing more functionality into smartphones, tablets, and wearable devices, while medical technology companies are developing minimally invasive surgical tools and implantable devices that require microscopic components.

These applications demand micro-transformers and inductors that maintain high efficiency and signal integrity despite their diminutive size. Standard equipment used for conventional coil winding cannot handle the serial production of micro coils, necessitating specialized machinery engineered for extreme precision.

The market expansion is particularly evident in the medical device sector, where micro coils are essential for catheters, guidewires, and interventional tools. Advanced micro-winders can now handle wire diameters as small as 0.001 inches on mandrels measuring just 0.010 inches, using closed-loop filar tension control systems that maintain consistent quality throughout the winding process.

This level of precision enables manufacturers to produce coils with outer diameters smaller than 30 microns, pushing the boundaries of what is physically possible in medical device miniaturization.

Key Trends Shaping the Industry

AI-Powered Smart Winding Systems

Artificial intelligence has emerged as a game-changing force in micro-winding technology, transforming machines from automated tools into intelligent manufacturing partners.

AI algorithms now optimize winding patterns in real-time, adjusting parameters dynamically based on sensor feedback to predict maintenance needs before breakdowns occur. This predictive capability significantly reduces downtime and extends machine lifespan, addressing one of the costliest challenges in high-precision manufacturing.

The intelligence embedded in modern systems goes beyond simple automation. Innovative AI platforms can learn from production data to make instantaneous adjustments when wire material properties vary slightly in tensile strength or thickness.

The machine automatically compensates to maintain winding consistency, effectively eliminating human error and material waste. For manufacturers producing micro coils for critical applications like aerospace sensors or implantable medical devices, this autonomous quality assurance represents a fundamental shift in production reliability.

IoT Integration and Industry 4.0 Connectivity

The Internet of Things has redefined manufacturing possibilities by connecting micro-winding machines to broader production ecosystems. IoT-enabled devices allow remote monitoring and control, enabling operators to track productivity metrics, energy consumption, and equipment wear through cloud-based dashboards.

This connectivity creates a fully synchronized intelligent factory where coil-winding machines communicate seamlessly with other systems across the production line.

In 2025, IoT-enhanced machines contribute to a holistic manufacturing environment that boosts output while enhancing safety and quality control. The integration extends to real-time data analytics that identify patterns in winding behavior, enabling continuous process improvement.

Manufacturers can now access historical performance data, compare production batches across different shifts or facilities, and implement standardized quality protocols that ensure consistency at scale.

This level of connectivity is particularly valuable for companies managing multiple production sites or serving clients with stringent documentation requirements.

Precision Robotics and Multi-Axis Control

The mechanical capabilities of micro-winding machines have advanced dramatically with the adoption of precision robotics. Modern systems frequently incorporate 6-axis robotic arms and ultra-high-precision stepper motors that enable handling of complex winding geometries previously considered impractical.

Whether producing toroidal coils or asymmetric shapes for specialized applications, today’s machines offer unprecedented flexibility in coil design.

This robotic precision proves especially critical in industries where the slightest deviation can have significant consequences. Medical device manufacturers require coil windings within 100-micron tolerances, with inline vision inspection systems confirming pitch accuracy in real-time.

The aerospace sector similarly depends on miniaturized, reliable components that withstand extreme environmental conditions while maintaining performance specifications.

Six-axis control allows for precise wire positioning and tension management throughout the winding process, ensuring each coil meets exacting standards without manual intervention.

Ultra-Fine Wire Handling Capabilities

The fundamental challenge in micro-winding lies in manipulating wires that are thinner than a human hair. Leading manufacturers have developed proprietary technologies to handle wires down to 59 AWG, working with materials that are five to ten times thinner than human hair. This capability requires innovations across multiple aspects of the winding process, from tension control to termination methods.

Specialized tensioning systems maintain consistent filar tension from 5 grams to 600 grams during the entire wind, adjusting recipe-controlled parameters automatically to accommodate different wire gauges and coil geometries.

The machines incorporate microscopes and real-time error correction mechanisms that detect minute variations in wire placement, enabling immediate corrective action.

For ultra-fine wires, traditional welding and soldering methods prove destructive, leading manufacturers to develop cutting-edge thermo-pressure bonding technologies that enable precise connections at high temperatures without damaging the delicate conductors.

Miniaturization for Medical and Wearable Electronics

The medical device industry represents the most demanding application domain for micro-winding technology, with requirements that extend beyond size constraints to include biocompatibility, reliability, and traceability. Micro coils for minimally invasive devices must be manufactured using medical-grade materials with tight tolerances and ultra-precision, achieved through advanced fine wire winding techniques.

Implantable devices present additional challenges, as coils must function reliably for years within the human body while minimizing footprint. Manufacturers have responded with compatible winding systems that maintain sterile environments throughout production.

The ability to produce coils with thousands of turns using wire as thin as 8 microns enables the development of next-generation implants that improve patient outcomes while reducing surgical invasiveness. These advances are directly transferable to wearable electronics, where comfort and battery life depend on compact, efficient inductive components.

Challenges and Innovative Solutions

Despite remarkable progress, micro-winding technology faces ongoing challenges that drive continuous innovation.

Requires tight tolerances:

Precise positioning and alignment of coil windings require tight tolerances to achieve desired electrical characteristics, with even microscopic deviations potentially compromising performance.

The industry has responded with integrated vision inspection systems that verify winding pitch within micron-level tolerances, automatically triggering rework functions when errors are detected.

Material handling

Material handling remains a critical concern, as ultra-fine wires are susceptible to damage from environmental factors, mechanical stress, and electrostatic discharge.

Modern winding machines incorporate specialized feeders, guides, and tensioning systems designed specifically for delicate materials. Recipe-driven product changeovers enable manufacturers to switch between different coil specifications with minimal downtime, a crucial capability for companies serving diverse markets.

Sustainability

Sustainability has emerged as an important consideration, with manufacturers incorporating energy-efficient components and eco-friendly processes to reduce carbon footprint and waste generation.

This aligns with broader movements toward sustainable manufacturing practices, where the emphasis on minimizing environmental impact extends to every production stage.

Future Outlook and Emerging Possibilities

Looking ahead, the evolution of micro-winding machines shows no signs of slowing. Industry experts anticipate the development of fully autonomous winding lines driven by generative AI that can optimize coil designs in real-time based on performance requirements.

Machine learning algorithms may soon analyze electromagnetic performance data to suggest winding topologies that maximize efficiency for specific applications, effectively creating custom coil designs algorithmically.

Conclusion

Micro-winding machines have evolved from specialized equipment into essential enablers of the electronics revolution. The convergence of AI intelligence, IoT connectivity, precision robotics, and advanced materials handling has created manufacturing capabilities that were science fiction just a decade ago.

As devices continue shrinking while demanding higher performance, the role of micro-winding technology becomes increasingly critical across medical, consumer, industrial, and aerospace applications.