Threads of Tomorrow: Innovation and Automation in Winding Machine Technology

Introduction

Manufacturers everywhere are feeling a quiet but undeniable shift in how winding machines are viewed on the factory floor. Not long ago, these machines were seen as dependable workhorses. These are necessary to get the job done, but rarely the focus of ambitious strategic planning. Fast forward now, and that old attitude is quickly being replaced. Executive teams and plant managers are now asking tough questions: How can we keep up as demand patterns fluctuate, product designs grow more complex, and the rest of the world races toward smarter production?

This is no longer just about upgrading a few motors or installing a faster PLC. The decisions being made around winding technology are directly linked to core goals like controlling costs, hitting ever-higher quality benchmarks, and building resilience against the next market disruption. Amid new customer expectations and tighter resource constraints, staying with conventional winding setups can mean falling behind for good. On the other hand, companies that rethink their winding approach to embrace the latest innovations in automation, data, and integration stand to set the pace for their entire sector.

At its core, the future of winding machines isn’t defined by shiny features or futuristic hype. It’s based on how well machines adapt to new yarns, deliver traceable data on every spool, or self-correct before a micro-flaw becomes a batch-wide disaster. The trends now sweeping the industry are reshaping what manufacturers can expect not just in output, but in reliability, transparency, and bottom-line performance. As the next generation of winding machines emerges, the real question is no longer if change is coming but how prepared each manufacturer will be to make the most of it.

Pushing the Frontiers of Precision

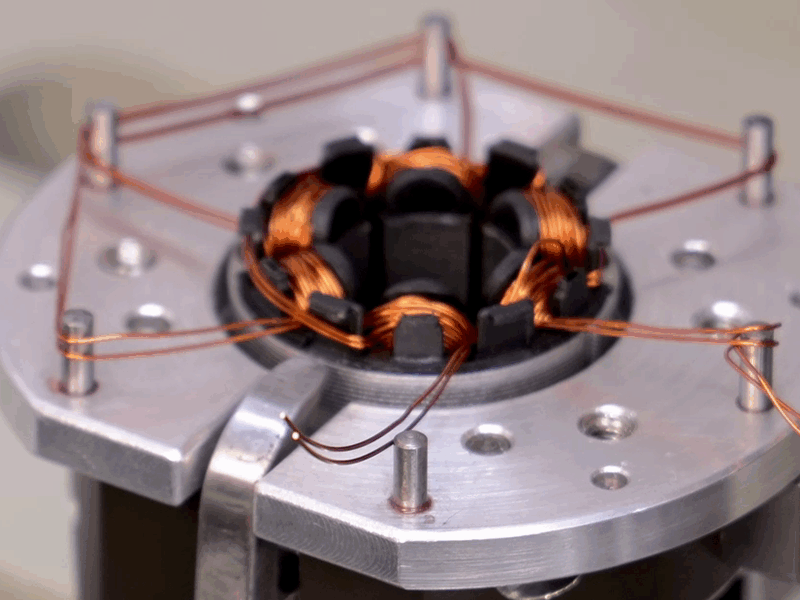

The winds of change have swept through winding halls before, but no force has altered the landscape as fundamentally as the integration of high-level automation. Automated winding machines have rewritten the norms for accuracy and output, with computer-controlled platforms that calibrate, monitor, and correct every detail in real-time. This isn’t automation as mere repetition; it’s automation as anticipation, reacting to data, learning from cycles, and optimizing for quality at each turn.

The outcome is increased productivity and significantly reduced error rates. Such machines can now handle a wider array of designs, adapt recipes on demand, and significantly reduce setup and changeover times. Factories equipped with new-generation winding automation quickly realize the competitive advantage in both speed and cost, preparing them for the unpredictable demands of tomorrow’s market.

The Smart Manufacturing Revolution

Smart manufacturing is more than a catchphrase; it is the connective tissue between digital intent and physical outcome. For winding machines, this has meant the adoption of IoT (Internet of Things) sensors, live production analytics, and cloud-based controls. Through these innovations, the once-isolated winding station becomes a networked node in a much larger ecosystem.

With predictive maintenance, winding machines now avert unplanned downtime by alerting teams before parts fail, leveraging production data accumulated over thousands of cycles. Real-time parameter adjustments cater to the specific properties of each batch of material, guaranteeing consistent quality. These smart features make the entire process more transparent, flexible, and resilient. These are the hallmarks of smart factory, where every asset counts and every outcome is measured.

AI, Machine Learning, and Adaptive Innovation

Artificial intelligence and machine learning have recently accelerated the pace of winding machine evolution. Machines today are trained with mountains of historical data, enabling them to detect subtle shifts in material quality, forecast optimal winding parameters, and adapt to variable production goals with minimal human intervention. For manufacturers, this means new benchmarks for quality assurance, material efficiency, and lead time reduction.

AI-driven winding machines are learning to optimize every run, even making small, data-driven tweaks for energy efficiency or resource savings. As algorithms improve, the vision is for winding machines to anticipate market changes, production bottlenecks, and even operator preferences. They become proactive partners in continuous improvement and innovation on the shop floor.

The Connected Winding Floor

One of the defining trends for the future is seamless digital integration. Winding machines are now expected to communicate with ERPs, MES systems, quality management tools, and even customers’ own supply networks. Open communication protocols promote this integration, ensuring that every step in the production chain is visible, traceable, and auditable.

For manufacturers, the benefits include reduced inventory overhead, synchronized production runs, rapid customizations for on-demand orders, and powerful data analytics to improve performance and strategic planning. As more operations adopt smart manufacturing standards, winding machines will play a central role in linking enterprise goals with the realities of daily production.

Customization and Sustainability

Another shift on the horizon is the rise of bespoke winding solutions and an increasing focus on sustainability. As machines become smarter, they support rapid switching between different product types, lot sizes, and winding geometries, enabling manufacturers to offer mass customization without incurring legacy costs. This flexibility is a major asset in industries where demand constantly changes, from electronics to automotive to medical devices.

Simultaneously, new winding technologies are being designed for reduced energy usage, minimal waste generation, and compatibility with recycled or bio-based materials. Winding machines are being equipped with environmental impact dashboards, giving decision-makers the tools to measure and minimize their carbon footprint while maintaining peak operational performance.

Human-Machine Synergy: Evolving Workforces and Roles

As automation and AI redefine manufacturing, the role of the human operator is also evolving. Modern winding machines, with intuitive touch interfaces, AR-guided maintenance, and machine-assisted troubleshooting. This enables workers to become supervisors of complex digital processes rather than just stewards of equipment. Training times are reducing, and cross-functional teams can manage more machines at scale, further amplifying the reach and impact of skilled professionals.

The future workforce will not be replaced but empowered. They will be freed from the grind of constant manual adjustment. Employees can focus on process innovation, system improvement, and creative problem-solving, driving greater value for the entire enterprise.

The Next Chapter in Winding Technology

What lies over the horizon? The next decade promises winding machines that feature full self-optimization, use of digital twins for rapid prototyping and machine tuning, and ever-closer collaboration with upstream and downstream robotics. As edge computing and 5G spread, local and cloud computational resources will allow winding systems to respond to real-world changes at lightning speed.

For manufacturers, embracing these trends isn’t simply about staying current. It’s about winning in a marketplace defined by responsiveness, resilience, and relentless innovation. By integrating the newest automation and smart manufacturing advancements, winding machines will keep their pivotal status, serving as both movers of wire and catalysts of transformation from factory floor to the final product.

Conclusion

The winding machine, once viewed as a mere utility on the shop floor, is poised to become the nerve centre of tomorrow’s smart manufacturing facilities. Future trends and relentless innovation will usher in machines that are not just faster or more precise, but fundamentally more intelligent and connected. The promise is clear. Those manufacturers who invest in smart, adaptive winding technology today will be the leaders of their industries tomorrow.