The Critical Role of Capacitor Winding Machines in Modern Electronics Performance

Introduction

In the relentless race for faster, smaller, and smarter electronics, the margin for error has all but vanished. Today’s devices are powering our homes, driving our cars, and connecting us across continents. In these circumstances demand is not just for innovation, but also for absolute consistency and reliability from every single component. Nowhere is this more critical than with capacitors, the tiny powerhouses that stabilize circuits, filter signals, and safeguard the performance of the world’s most advanced technologies.

Yet, few pause to consider the extraordinary journey these capacitors undertake before they ever reach a circuit board. Behind every high-quality capacitor lies a story of engineering precision, where even the slightest inconsistency can ripple through an entire system. The secret to this reliability is the evolution of capacitor winding machines. A highly specialized, automated marvels that have quietly sparked a revolution in how electronic components are crafted. These machines are not just tools; they are the gatekeepers of consistency, performance, and quality in modern electronics, setting the standard for excellence with every meticulously wound layer.

The Foundation of Electronic Excellence

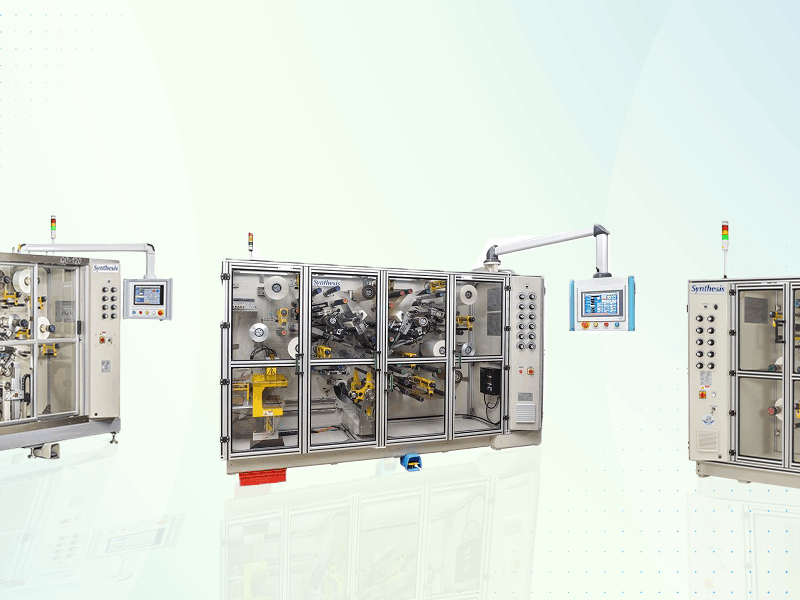

Capacitor winding machines represent far more than mere manufacturing equipment. They are sophisticated engineering systems that embody decades of technological advancement and precision manufacturing expertise. These specialized machines automate the process of winding dielectric films and electrodes to form the core structure of various capacitor types, from aluminium electrolytic to metalized polypropylene variants.

The precision required in capacitor manufacturing cannot be overstated. Modern electronics demand components that operate flawlessly across extreme temperature ranges, varying voltage conditions, and diverse environmental challenges. A single deviation in winding tension, film alignment, or layer thickness can compromise the entire component’s performance, potentially leading to device failure, safety hazards, or reduced operational lifespan.

Engineering Precision Through Advanced Automation

The evolution of capacitor winding technology has transformed from manual, labor-intensive processes to highly automated systems that deliver consistency and quality. Modern automatic capacitor winding machines incorporate sophisticated control systems, precision motion controllers, and real-time monitoring capabilities that ensure each capacitor meets exact specifications.

These advanced machines feature programmable winding parameters, automated tension control, and precise material handling systems that can accommodate various film and foil materials. The integration of CNC motion control and PLC systems enables manufacturers to achieve micron-level accuracy while maintaining high production speeds. This level of precision is essential for producing capacitors with tight tolerances and reliable electrical performance.

The Critical Role of Consistency in Manufacturing

Consistency in capacitor manufacturing extends beyond mere dimensional accuracy. It encompasses the uniformity of electrical characteristics, mechanical properties, and long-term reliability. Capacitor winding machines achieve this through several key technological innovations:

Precision Tension Control: Advanced servo-driven systems maintain consistent film tension throughout the winding process, ensuring uniform dielectric thickness and optimal electrical properties. This precision prevents variations that could lead to capacitance drift, voltage rating degradation, or premature failure.

Automated Quality Monitoring: Modern machines incorporate real-time capacitance measurement capabilities, allowing for immediate adjustments to maintain exact specifications. This continuous monitoring ensures that each capacitor meets predetermined electrical characteristics before leaving the production line.

Environmental Compensation: Sophisticated control systems automatically adjust for temperature, humidity, and other environmental factors that could affect winding consistency. This ensures stable production quality regardless of external conditions.

Meeting the Demands of Modern Electronics

Today’s electronics industry presents unprecedented challenges for component manufacturers. The miniaturization trend demands smaller capacitors with higher capacitance density, while the push toward electric vehicles and renewable energy systems requires components capable of handling extreme operating conditions. Capacitor winding machines have evolved to meet these demanding requirements through several technological advances:

High-Speed Production: Modern machines can produce thousands of capacitors per hour while maintaining precise quality standards. This high-speed capability is essential for meeting the massive demand from electronics manufacturers worldwide.

Versatile Material Handling: Advanced winding systems can process various dielectric materials, including metallized polypropylene, aluminium foil, and specialized films required for high-voltage applications. This versatility enables manufacturers to produce capacitors for diverse electronics applications.

Automated Testing Integration: State-of-the-art machines incorporate comprehensive testing capabilities that verify electrical performance, mechanical integrity, and reliability characteristics. This integration ensures that only components meeting strict quality standards reach the market.

The Impact on Electronic Component Performance

The precision achieved through advanced capacitor winding technology directly translates to superior performance in electronic devices. High-quality capacitors produced by precision winding machines exhibit several critical characteristics:

Enhanced Reliability: Consistent winding processes result in capacitors with predictable failure rates and extended operational lifespans. This reliability is crucial for electronics applications where component failure could have serious consequences.

Improved Electrical Performance: Precise winding ensures optimal dielectric characteristics, low equivalent series resistance, and stable capacitance values across operating conditions. These properties are essential for maintaining signal integrity and power system stability.

Superior Environmental Resistance: Uniform winding density and consistent material properties enhance the capacitor’s ability to withstand temperature variations, mechanical stress, and electrical overstress conditions.

Industry Applications and Market Dynamics

The global market for capacitor winding machines reflects the growing importance of precision manufacturing in electronics. Industries ranging from automotive and aerospace to consumer electronics and industrial automation rely on high-quality capacitors for their products’ performance and reliability.

Automotive Electronics: The electric vehicle revolution has created massive demand for high-performance capacitors capable of handling extreme operating conditions. Precision winding machines enable manufacturers to produce automotive-grade components that meet stringent reliability requirements.

Industrial Applications: Power systems, motor drives, and industrial control equipment require capacitors with exceptional performance characteristics. Advanced winding technology ensures these critical components can handle demanding industrial environments.

Consumer Electronics: The miniaturization trend in smartphones, tablets, and wearable devices demands smaller capacitors with higher capacitance density. Precision winding machines enable manufacturers to produce compact components without compromising performance.

Quality Assurance and Standards Compliance

Modern capacitor winding machines incorporate comprehensive quality assurance systems that ensure compliance with international standards. These systems include automated inspection capabilities, statistical process control, and traceability features that enable manufacturers to maintain consistent quality throughout production.

The integration of advanced quality control systems ensures that each capacitor meets or exceeds industry standards for performance, reliability, and safety. This compliance is essential for manufacturers seeking to compete in global markets and maintain customer confidence.

Future Trends and Technological Advancement

The future of capacitor winding technology promises even greater precision, efficiency, and capability. Emerging trends include artificial intelligence integration for predictive maintenance, advanced material handling systems for next-generation dielectric materials, and enhanced automation for lights-out manufacturing operations.

These technological advancements will enable manufacturers to produce increasingly sophisticated components while maintaining the consistency and quality standards demanded by modern electronics applications. The continuous evolution of capacitor winding technology ensures that manufacturers can meet the challenges of tomorrow’s electronic devices.

Conclusion

Capacitor winding machines stand as critical enablers of modern electronics manufacturing, transforming raw materials into the precision-engineered components that power our digital world. Their ability to achieve unprecedented consistency, quality, and performance makes them indispensable tools for manufacturers seeking to compete in today’s demanding electronics market.

As the electronics industry continues to evolve, driven by trends toward miniaturization, electrification, and advanced functionality, the importance of precision capacitor manufacturing will only grow. Companies that invest in advanced winding technology position themselves to meet these challenges while delivering the high-quality components that define excellence in modern electronics.

The future belongs to manufacturers who understand that superior performance begins with precision manufacturing and capacitor winding machines provide the foundation for that precision.