Sensing the Future: How Smart Sensors are Transforming Winding Machine Data Monitoring

Why Guess When You Can Know?

Manufacturing used to rely on intuition, experience, and periodic checks to keep winding machines running smoothly. Those days are rapidly disappearing. Today, data are measured in milliseconds and analysed on the fly. This is becoming the heartbeat of performance, efficiency, and reliability. Now, when a winding machine needs to adjust, it doesn’t wait for a scheduled maintenance check or a calculated guess by the operator. Instead, smart sensors embedded throughout the system are constantly listening, measuring, and feeding back real-time information. There is no longer a need to settle for “good enough” when a precise, measurable, and actionable level of insight can be achieved at every coil, spool, and spindle.

In this new setup, integration isn’t just about adding a few digital readouts. It’s a reset of how manufacturers approach every aspect of efficiency, from preventative maintenance to pinpoint process control. With smart sensors and advanced data monitoring, winding machines aren’t simply automated. They are responsive, adaptive, and smarter with every cycle. This transformation is not hype; it’s a live shift in how products are made and companies that tap into real-time, sensor-driven intelligence are already gaining the edge on productivity, quality, and cost.

Smart Sensors: The Nerve System of Next-Gen Winding

The core function of a smart sensor goes well beyond simple detection. These components act as the nerve system for the entire winding operation, capturing an array of parameters such as temperature, vibration, tension, speed, and even moisture. Rather than generating raw signals alone, smart sensors interpret environmental and operational data, digitize it, and communicate immediately with the powerful control systems integrated in modern winding machines.

This evolution allows the collection of high-resolution, real-time data at every critical point of the manufacturing cycle. Using such granular feedback, winding machines can self-correct to minimize error, notify operators before minor deviations become faults, and tailor their process to each unique production lot. In practical terms, this means fewer breakdowns, higher yield, and a measurable increase in process efficiency.

Integration: Beyond “Add-On” to Holistic Intelligence

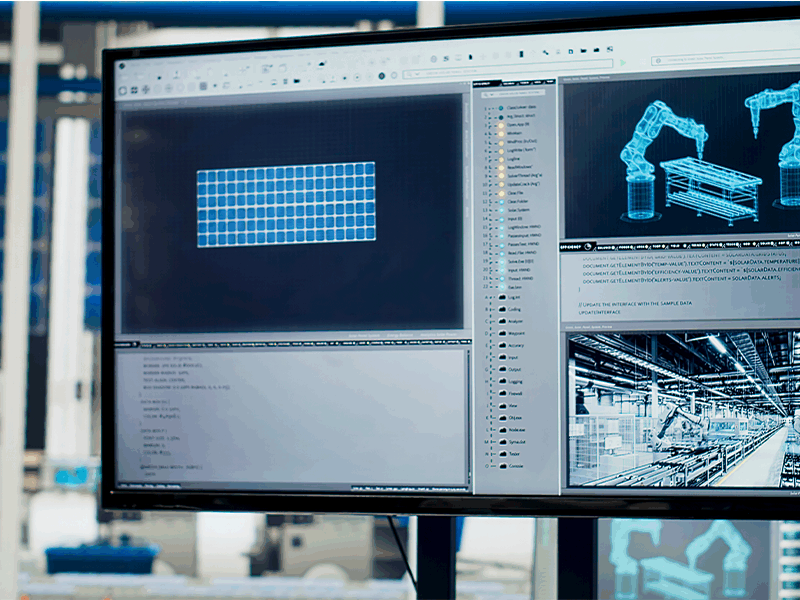

True sensor-driven transformation happens when smart sensors are not just bolted onto old systems but holistically integrated into the design and control logic of the machine itself. Integration means that data from the sensors isn’t siloed or analysed after the fact. It is processed in real-time by the automation platform, directly informing adjustments to motor speed, wire tension, or environmental controls.

This tightly coupled system allows for immediate response to issues such as a change in raw material characteristics, unexpected spindle vibration, or gradual temperature drift. In effect, the winding machine becomes a dynamically adjusting organism, maintaining optimal conditions and quickly troubleshooting minor issues before they disrupt the entire production flow. This level of responsiveness is foundational to smart factories and a must for any operation prioritizing efficiency.

Data Monitoring: The Move to Predictive and Preventive

Smart sensor integration fundamentally changes what’s possible with data monitoring. Traditional approaches depended on fixed schedules and human inspection, leaving many problems undetected until significant downtime or defects had already occurred. With continuous, automated monitoring, data about every operation and anomaly is captured, logged, and analysed. This method enables both instant alerts and long-term process improvement.

Machine learning tools and AI-powered analytics further expand these possibilities. Over time, the system “learns” normal versus abnormal behaviour patterns and can proactively flag subtle shifts. These shifts includes patterns such as a slowly worsening bearing, an uptick in tension variation, or environmental changes that consistently impact coil consistency. Instead of reacting to failures, teams can anticipate and prevent them, achieving new heights of reliability and process longevity.

Real-Time Efficiency: From Awareness to Action

Efficiency isn’t just about speed. It’s about responding to the right data at the right moment. Real-time data provides the situational awareness required to optimize every production parameter, whether that means ramping up output, maintaining tight tolerances, or saving energy during off-peak cycles. With smart sensors delivering a constant stream of actionable information, operators can transition from “watch and wait” to “predict and adjust” as issues start to emerge.

This shift doesn’t just benefit uptime. It also drives consistent product quality, as adjustments to winding speed, tension, or temperature can be executed before any variation impacts the final output. In environments where one faulty coil can lead to production stoppages, wasted material, or costly rework, real-time efficiency is the difference between merely getting the job done and excelling in a competitive marketplace.

Efficiency Gains and the Business Case

The return on integrating smart sensors into winding machines is both operational and strategic. Reduced unplanned downtime, better material utilization, less energy waste, and more consistent product quality all translate directly to lower costs and higher profitability. The intelligence generated by smart sensors supports strategic decision-making and provides vital documentation for compliance or future process audits.

Moreover, real-time data monitoring unlocks new service models, such as remote diagnostics and performance benchmarking across multiple sites. Manufacturers can compare lines, identify underperformers, and share best practices based on hard evidence, not just anecdote or gut feelings.

Tomorrow’s Winding Machines

Looking ahead, the integration of smart sensors is leading towards fully autonomous operations. Future winding machines may predict not just failures but optimal production profiles for different materials. These materials automatically reconfigure settings for new orders and even initiate their own maintenance routines. As Industry 4.0 matures, data generated by smart sensors will feed entire digital ecosystems, from supply chain management to customer-facing quality dashboards.

In this evolving world, the role of the operator will shift from hands-on troubleshooting to skilled analysis and continuous process optimization. They are supported by more precise and transparent data streams than ever before. The winners in this transition will be those who don’t just collect data, but who build entire operational cultures around integrating, interpreting, and acting on it.

Conclusion

Smart sensor integration and real-time data monitoring are quickly becoming the baseline for world-class winding operations. What once required skilled intuition is now routine process that is automated, precise, and constantly improving. For manufacturers, leveraging this intelligence is about more than keeping up. It’s about setting the pace, elevating efficiency, anticipating challenges, and building adaptable operations that can thrive in tomorrow’s marketplace.