Semi-Automatic Winding Machines: The Smart Middle Ground for Modern Manufacturing

Introduction

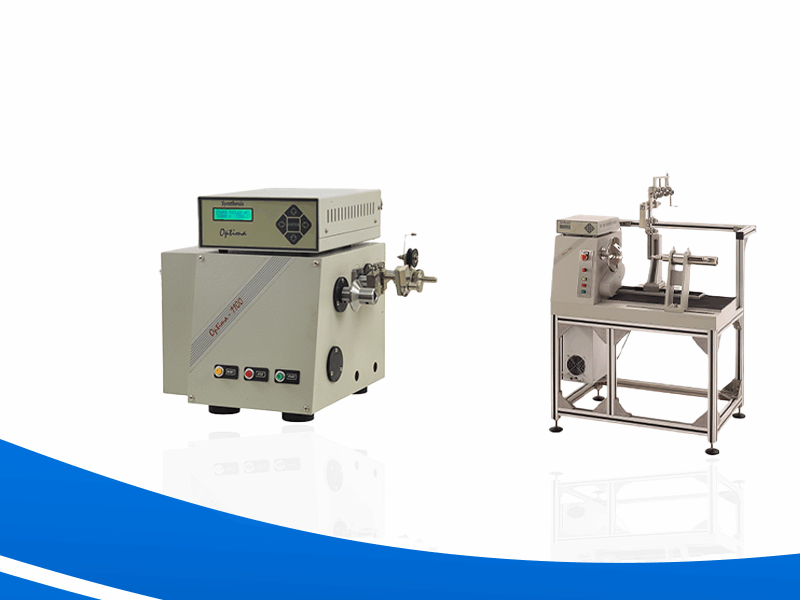

Imagine stepping onto a factory floor where most machines are punctuated by the attentive presence of skilled operators. Here, human expertise and smart automation work side by side, each enhancing the other. This isn’t a scene dominated by fully robotic assembly lines, nor is it a throwback to the days of entirely manual labour. Instead, it’s the new reality enabled by semi-automatic coil winding machines, a class of equipment that quietly transforms how coils are produced across industries.

While the spotlight often shines on either manual or fully automatic winding, semi-automatic machines occupy a unique and powerful middle ground. They offer manufacturers a way to achieve cost-effective coil production and remarkable flexibility, all while maintaining the level of quality of today’s market demands. Let’s explore how these machines are shaping the future of manufacturing, and why they may be the smart choice for your production line.

The Evolution of Coil Winding

For decades, coil winding was largely a manual process. Skilled workers would painstakingly wind wire onto forms, ensuring each turn was precise. While this method offered flexibility and hands-on control, it was slow, labour-intensive, and prone to inconsistencies. As technology advanced, fully automatic winding machines entered the scene, promising speed and uniformity. However, these systems often required significant investment and were best suited for high-volume, standardized production.

This left a gap for manufacturers who needed something in between. They needed machines that could deliver both efficiency and adaptability, without the high costs or rigidity of full automation. That’s where semi-automatic coil winding machines found their niche. By blending programmable controls with operator involvement, these machines allow businesses to scale up production, maintain quality, and quickly adapt to changing requirements.

The Value of a Hybrid Approach

The debate between manual vs. automatic winding is ongoing in the manufacturing world. Manual winding is still valued for prototyping, small batches, and highly customized coils. This is mainly because it allows for immediate adjustments and close quality monitoring. However, as batch sizes grow or product lines diversify, manual processes can become bottlenecks, slowing down production and increasing labour costs.

On the other hand, fully automatic winding machines excel in mass production environments. They deliver high speed, repeatability, and lower per-unit costs on a scale. Yet, their complexity and upfront investment can be prohibitive for smaller manufacturers or those with frequently changing product specifications.

Semi-automatic coil winding machines bridge this divide. They automate repetitive and precision-critical steps. These include steps such as wire feeding, tension control, and turn counting, while allowing operators to intervene when needed. This hybrid approach means manufacturers can enjoy the best of both worlds, the flexibility to handle custom orders and the efficiency to meet growing demand.

Cost-Effective Coil Production for Growing Businesses

One of the most compelling reasons manufacturers turn to semi-automatic machines is the promise of cost-effective coil production. These machines require a lower initial investment compared to fully automatic systems, making them accessible for small and medium-sized enterprises. At the same time, they significantly reduce the labor hours needed for each coil, as operators are freed from the most tedious and error-prone tasks.

Semi-automatic machines also help minimize material waste. With features like programmable tension control and real-time error detection, they ensure that each coil is wound precisely to specification. If a problem arises—such as a wire misalignment or a break—the operator can pause the process, correct the issue, and resume winding without scrapping the entire coil. This level of control translates into direct savings on both materials and time.

Additionally, these machines are often modular, allowing businesses to scale production by adding more winding stations as demand increases. This scalability is a key advantage for manufacturers who want to grow without overcommitting to the high costs and complexity of full automation.

Flexible Winding Solutions for a Dynamic Market

In today’s fast-evolving industries, flexibility is more than a luxury, it’s a necessity. Flexible winding solutions are essential for manufacturers who serve diverse markets, produce a variety of coil types, or frequently update their designs. Semi-automatic coil winding machines shine in these scenarios.

Unlike rigid automated systems, semi-automatic machines can be quickly reprogrammed to accommodate different winding patterns, wire gauges, and coil sizes. Operators can easily switch between product types with minimal downtime, making it feasible to fulfill both standard and custom orders in the same facility. This agility is especially valuable in sectors like electronics, medical devices, and R&D environments, where innovation and customization drive success.

For example, a manufacturer producing custom transformers for industrial applications can use semi-automatic machines to adjust winding parameters on the fly. If a client requests a new configuration, the operator can modify the settings, test a prototype, and move to production without waiting for programming changes. This rapid response capability is a competitive advantage in markets where speed and adaptability matter.

Real-World Applications

Semi-automatic coil winding machines are making a significant impact across a wide range of industries. In the automotive sector, they are used to producing ignition coils, sensors, and solenoids in moderate volumes. This will balance the need for precision with the flexibility to handle multiple part numbers. In the electronics industry, these machines enable efficient production of inductors, chokes, and small transformers, supporting both mass-market and niche products.

Medical device manufacturers rely on semi-automatic winding machines to create highly specialized coils for implants, diagnostic equipment, and therapeutic devices. The ability to combine automation with hands-on oversight ensures that each coil meets strict regulatory standards for quality and safety.

In the renewable energy sector, the demand for custom windings in solar inverters and wind turbine generators is growing rapidly. Semi-automatic machines offer the adaptability to produce coils for both standard and emerging technologies.

Key Features of Semi-Automatic Machines

What makes semi-automatic coil winding machines so effective in modern manufacturing? Several features contribute to their widespread adoption:

Programmable Controls: Operators can set winding patterns, turn counts, and tension parameters, ensuring accurate results for every coil.

Operator Intervention: The ability to pause, inspect, and adjust during the winding process allows for real-time quality control and troubleshooting.

Versatility: These machines can handle a wide range of wire types, diameters, and coil geometries, making them suitable for diverse applications.

Ease of Use: Intuitive interfaces and straightforward setup mean that operators can be trained quickly, reducing onboarding time and minimizing errors.

Safety: By automating the most repetitive and potentially hazardous tasks, semi-automatic machines help create a safer work environment.

Future Trends

As manufacturing continues to evolve, so do the capabilities of semi-automatic winding machines. The integration of IoT (Internet of Things) is enabling real-time monitoring of machine health, production metrics, and maintenance needs. Predictive analytics can alert operators to potential issues before they cause downtime, further improving efficiency and reliability.

Artificial intelligence is also beginning to play a role, with some machines now able to suggest optimal winding parameters based on the type of wire and coil being produced. This not only enhances quality but also reduces the learning curve for new operators.

Sustainability is another area of focus. Modern semi-automatic machines are being designed with energy-efficient motors and recyclable materials. This helps manufacturers reduce their environmental footprint while maintaining high standards of performance.

Best Practices

To maximize the benefits of semi-automatic winding machines, manufacturers should consider several best practices:

Assess Production Needs: Understand your typical batch sizes, product variety, and customization requirements before selecting a machine.

Invest in Training: Ensure operators are well-trained in both the technical and safety aspects of the machines.

Plan for Scalability: Choose systems that can grow with your business, either by adding more stations or upgrading features.

Leverage Data: Use available analytics and monitoring tools to optimize production and anticipate maintenance needs.

Maintain Flexibility: Regularly review and update winding programs to keep updated with evolving market demands.

Conclusion

In the ongoing evolution of manufacturing, semi-automatic coil winding machines have proven themselves to be more than just a compromise between manual and automatic processes. They represent a strategic choice for businesses looking for cost-effective coil production and flexible winding solutions without sacrificing quality or scalability.

By bridging the gap between manual vs. automatic winding, these machines empower manufacturers to respond quickly to customer needs, control costs, and maintain a high standard of craftsmanship. As technology advances, their role will only grow more importantly, helping companies of all sizes compete and thrive in a demanding world. If your production line needs the perfect blend of adaptability, precision, and efficiency, it’s time to consider what semi-automatic winding machines can do for you.