Precision in Practice: Winding Machines for Medical Device Innovation

Introduction

Before a surgeon’s steady hands deliver a life-changing procedure, or a patient receives a critical diagnosis, an invisible chain of technological events must unfold. Those events begin long before the hospital doors open. At the core of this story lies the winding machine. In the manufacture of cutting-edge medical equipment, winding machines operate with clockwork precision. They shape the coils, motors, and micro components that form the backbone of modern healthcare devices.

Their contribution may be hidden beneath sleek exteriors of diagnostic scanners, inside implantable pumps, or wrapped around the delicate cathodes powering respiratory support, but the value they deliver is nothing short of transformational.

The Foundation of Medical Reliability

Precision is the language winding machines speak fluently, and in the medical arena, perfection is mandatory. Electromagnetic coils are essential for MRI machines, pacemakers, and infusion pumps, often require tolerances measured in microns. When a single mistake can compromise safety or render a device unusable, the pressure to achieve flawlessness is enormous.

Winding machines answer this demand by managing tension, alignment, and layering with consistency, using advanced servo motors, adaptive sensors, and automated feedback mechanisms. And the result: every coil, every turn, is controlled for exact duplication. This is not simply about mechanical replication but about delivering trustworthy performance in environments where patient outcomes are on the line.

Enabling Healthcare Innovation Through Advanced Manufacturing

The role of these machines does not stop at the assembly line. Their influence reaches into the realm of innovation, allowing engineers to imagine and create new generations of medical devices. The rapid evolution of minimally invasive treatments including microcatheters and ultra-fine sensors has raised the bar for manufacturing requirements.

Today’s winding machines can handle extraordinarily thin wires, wind complex multi-filar patterns and switch operational modes on demand. This flexibility allows manufacturers to move quickly from prototype to scalable production, reducing time to market for new healthcare innovations and helping patients benefit from breakthroughs far sooner than before.

Consistency, Safety, and Compliance

In a world of strict regulation and critical scrutiny, safety is never negotiable. Winding machines support this in three major ways. First, their automated setup minimizes human error, reducing defects at the source. Second, integrated inspection systems using optical and electrical sensors verify the diameter, tension, and integrity of every winding in real time. Any deviation triggers immediate alerts, ensuring that potentially risky components never leave the assembly floor. Third, traceability is built into every step, documenting the exact production details for every coil, motor, and micro component.

This means that, if a problem ever arises in the field, manufacturers can track its lineage back to the very spindle or batch involved, supporting robust quality control and swift corrective action.

Meeting the Demands of Modern Healthcare

Efficient production is essential in an industry as dynamic as healthcare. Increasing market volatility, shifting regulatory demands, and the need for quick scale-ups in emergencies like pandemics require manufacturing processes that are robust yet agile. Winding machines have risen to this challenge by integrating modular designs, quick-change tooling, and software-driven automation that minimize downtime and maximize output.

They allow device makers to ramp up or adjust production swiftly, producing thousands of reliable coils for ventilators or diagnostic sensors in a matter of hours rather than days. In times of crisis, this capacity is not just commercially valuable, it can be a matter of public health.

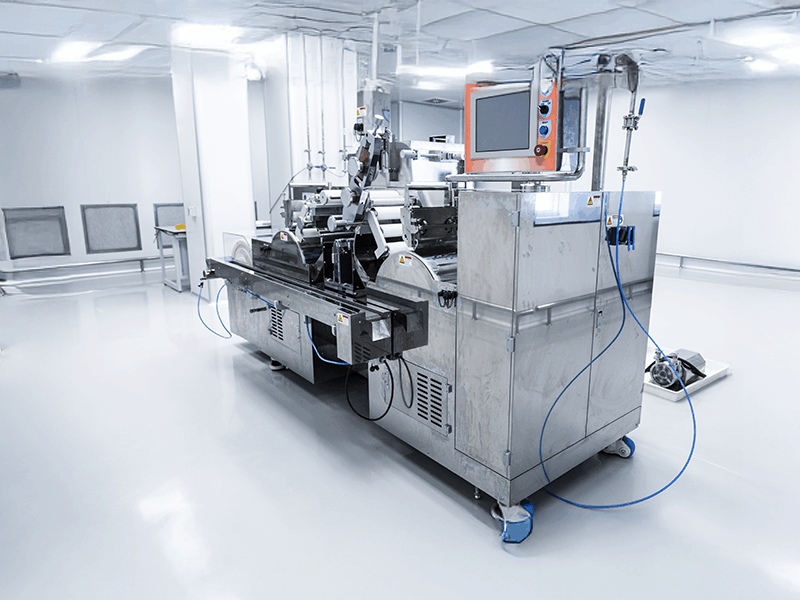

The benefits extend to medical textiles and consumables as well. The winding process ensures that bandages, surgical threads, and other wound care products are produced with even tension, accurate length, and hygienic standards that reduce infection risk. Machines built for the medical sector feature stainless steel parts, easy-clean surfaces, and sealed drive units, supporting strict sanitation requirements set by global health authorities.

In fields where patient comfort is as important as sterilization, winding precision makes every difference. Material science is another area illuminated by winding machine technology. The introduction of biocompatible wires, specialty coatings, and advanced insulation materials means that winding machines must be able to adapt seamlessly to new input types, geometries, and performance parameters.

Modern machines do so elegantly incorporate programmable logic, wire feeding innovations, and closed-loop feedback to handle everything from copper and silver to non-metallic threads and shape memory alloys. This capability is allowing manufacturers to explore and integrate new materials that improve patient safety, extend device lifespans, and enable once-unthinkable medical procedures.

Championing Safety and Reliability in Every Layer

The healthcare supply chain cannot afford bottlenecks, especially at the points that impact device safety and reliability. Here again, winding machines have become indispensable. Their continuous operation which often runs 24/7 ensures that hospitals, clinics, and device manufacturers receive a constant flow of critical components on time. Automated diagnostic features and predictive maintenance reduce the risk of machine downtime, further safeguarding the availability of medical equipment.

When a hospital needs a new batch of ventilator motors or a clinic awaits a shipment of infusion pumps, winding automation is the guarantee that the supply will arrive on schedule. Perhaps most importantly, winding machines help create trust between manufacturers and hospitals, doctors and patients, executives and regulatory bodies. Each component they produce carries within it the assurance of accuracy, compliance, and repeatability, qualities that underpin the reputation of medical device brands the world over. This is not just about technical achievement; it is about establishing and maintaining standards of care where the consequences of failure far outweigh commercial concerns.

Innovation is a constant in medicine, and winding technology continues to lead the way. Advances in IoT integration are enabling smart factories where winding machines are directly linked to global healthcare supply chains, adapting production rates in real time due to demand fluctuations or emergency needs. Artificial intelligence algorithms now enable machines to detect minuscule anomalies and optimize production parameters automatically, leading to even higher levels of precision and safety.

The Future: Innovation Without Compromise

Looking to the future, the merger of winding technology and medical device manufacturing promises even greater synergy. Next-generation devices, ranging from embedded diagnostic chips to bioelectronic implants will demand new levels of micro-manufacturing agility. Winding machines, built with adaptability and ever-evolving intelligence, are poised to deliver these capabilities, helping the medical industry continue its incredible journey of progress.

In the end, while winding machines may remain invisible behind the scenes, their influence is woven through every heartbeat monitor, imaging system, and therapeutic device in modern healthcare. Their unwavering dedication to precision, relentless pursuit of safety, and continuous drive for innovation ensure that patients benefit, manufacturers thrive, and the world remains a little healthier every day.