Innovative Software: The Revolution of Winding Machine Control

Introduction

The evolution of winding machines has caused the most significant shifts in manufacturing. Where heavy mechanical engineering and operator experience once dominated, a new array of software-driven solutions now dictates what peak performance means in coil, stator, and transformer production. Manufacturers seeking faster changeovers, exacting standards, and unshakable reliability know the differentiator is no longer simply hardware.

It’s the intelligence embedded in the software. Innovations in winding machine automation are enabling real-time control, next-level precision, and unprecedented adaptability. This turns code into competitive advantage for companies worldwide.

Software: The Foundation of Modern Winding Precision

Legacy winding machines depended on guesswork and periodic checks. Today, software powers advanced control systems that oversee tension, speed, and positional accuracy to the fraction of a millimetre. Integrated algorithms can instantly recalibrate pathing and adjust spindle or wire feed, applying correction at every point in the process.

Manufacturers use these capabilities to produce windings for electric vehicles, aerospace applications, and medical devices. This is where even a micro-variation can mean the difference between excellence and costly error. Innovative platforms incorporate digital twin technology, allowing production teams to run simulations and tweak process variables before physical manufacturing even begins.

This means material can be optimized, cycle times can be minimized, and risk can be dramatically reduced from the safety of a screen. For managers and technicians, software platforms are windows into every cycle and batch, giving them oversight and fine control like never before.

Real-Time Control Changes the Game

Arguably, the greatest benefit of modern winding software is real-time process management. With advanced sensor integration and intuitive dashboards, operators can see exactly how every winding is formed. This gives them the chance to intervene instantly if variations occur. Instead of finding faults after batches are run, software-driven winding machines detect anomalies, alert users, and often auto-correct without stopping the line. This ensures quality and consistency, clears bottlenecks, and keeps production moving.

Beyond quality, real-time control supports mass customization. If a company needs coils for multiple applications, systems can be switched, recipes loaded, and parameters pushed to the machine with just a few clicks. The result will be more flexible, and it will respond to new orders, short-run batches for prototyping, and far less downtime compared to mechanical-only setups.

Automation for Productivity and Uptime

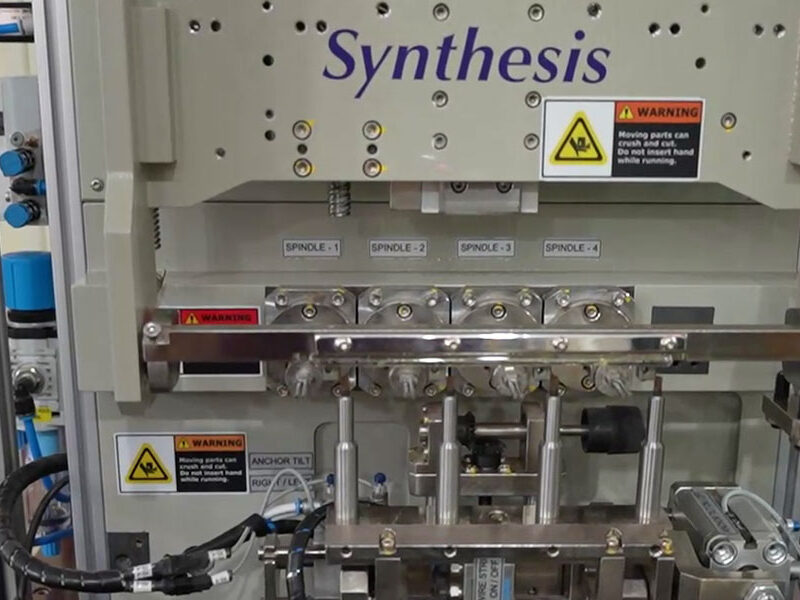

Automation is more than simply getting machines to repeat a task. In winding, it means orchestrating sequences across multiple axes, integrating predictive maintenance, and running multi-spindle operations efficiently. Software automation enables programmed diagnostics. With this, machines can schedule their own health checks, alert maintenance, and log wear and tear. This minimizes unscheduled downtime and keeps production lines running, while maximizing asset longevity.

Process automation also powers higher yields. By automatically compensating for tension changes or environmental shifts, winding machines maintain top performance across every batch, regardless of operator experience or shift changes. This leads to measurable cost savings, less scrap, and improved margins. Production managers now rely as much on software dashboards as they do on physical plant walkthroughs to monitor progress and resolve issues proactively.

Innovations Reshaping the Industry

Recent innovations include the use of artificial intelligence and machine learning for adaptive winding. Some platforms “learn” from previous cycles to optimize material usage, detect patterns that precede defects, and recommend process improvements. Manufacturers can test and refine new coil designs via simulation before switching real machines to new specs, greatly accelerating product development.

Robust software integration now means winding machines can communicate directly with ERP, MES, or quality management systems. This level of connectivity supports live tracking, instant QC logging, and compliance reporting. If a customer asks for proof of consistent quality or wants immediate feedback on a batch, modern software delivers with a few keystrokes.

Furthermore, open-source protocols and modular architecture ensure today’s software can receive upgrades and add features without overhauling hardware. A plant running five-year-old winding machines can accept the latest algorithms for wireless configuration, new winding geometries, or enhanced security. This helps in keeping capital investments up to date with minimum disruption.

The Human-Machine Partnership

As winding machine software evolves, it doesn’t replace operators. It enhances their ability and empowers them. Touchscreens, interactive guides, and on-demand support make training faster and troubleshooting intuitive. Teams can focus on process improvement and value creation since software handles repetitious monitoring and error-checking. Built-in help screens and guided calibration mean new hires become effective more quickly, while experienced staff use analytics for ongoing optimization.

Continuous professional development and knowledge-sharing become easier. With software logging every batch and parameter, teams can analyze outputs, share best practices, and refine methods for future runs. Manufacturers who embrace the human-machine partnership are consistently reporting higher productivity and employee satisfaction compared to rigid, hardware-only approaches.

Looking Forward: The Next Decade of Winding Software

In the near future, we’ll see software advancements driving even more adaptive automation and integrated analytics. Cloud-managed winding platforms, mobile oversight, and secure remote diagnostics will allow global manufacturers to optimize lines from anywhere. Innovations in data visualization will make production trends, quality alerts, and asset management accessible at a glance.

As bespoke and high-mix coil manufacturing grows more popular, scalability will depend on software’s ability to manage complexity without sacrificing control. Companies investing in flexible, upgradeable software infrastructure now will be best positioned to meet changing market requirements, new regulations, and rising customer expectations.

Conclusion: Raising Standards Through Software-Driven Control

It’s clear the modern winding machine can only reach its potential when powered by robust, innovative software. Precision is defined by how many variables are controlled and at what speed. Automation gains are realized when setups and recipes can be reconfigured in seconds. Ultimately, software transforms winding machines from static tools into strategic assets and thus enabling reliability, quality, and business agility for manufacturers of all sizes. Those who elevate their investment in software will find themselves leading the industry, coil after coil.