Holding It Together: The Critical Role of Tension Control in Winding Machines

Introduction

Step onto the floor of any factory where winding machines are at work, and you’ll sense a quiet order: spools turn, wires glide, and precision seems routine. Yet beneath this mechanical ballet, one force dictates the outcome of every coil and component, the force of tension. Like gravity holding the cosmos together, tension is the unseen but vital constant that determines whether the finished product will meet the strictest standards for quality, uniformity, and performance or fall short at the most critical junctures.

For manufacturers, tension is more than just a number on a gauge; it is the difference between seamless electrical flow and unwanted heat, between mechanical durability and premature breakdown. While automation and innovation are celebrated for revolutionizing winding technology, one truth remains: without mastery over tension, the promise of efficiency and control is forever out of reach. The importance of tension control is not merely technical. It’s the defining thread that weaves through every success story in high-performance winding.

The Essence of Quality and Uniformity

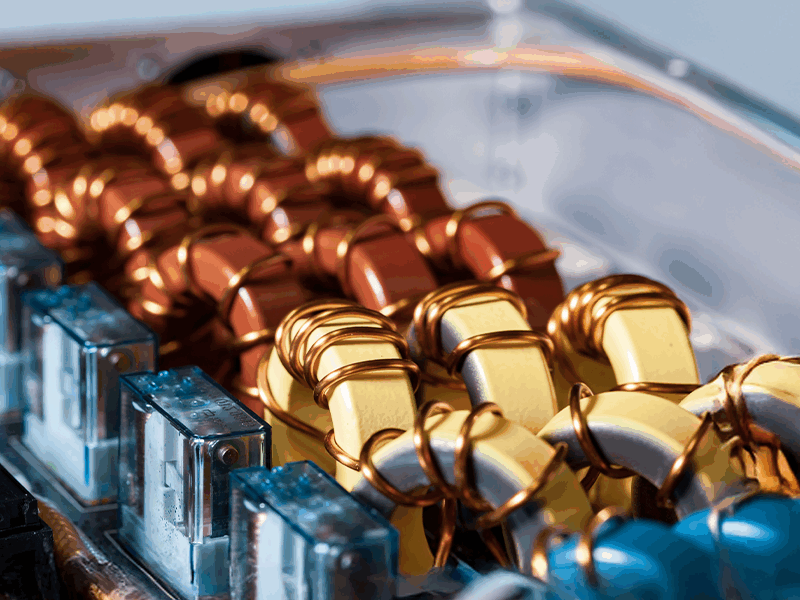

All winding processes, whether involving wires, yarns, textiles, or specialty fibres rely on controlled tension to achieve desired quality. Tension stretches the material as it is guided onto a core or bobbin, shaping how each layer forms and how tightly every loop is held in place. When tension is managed precisely, every segment of the coil is wrapped with uniform force, minimizing gaps, bulges, or irregular coverage. The result is extraordinary. Components emerge with consistent dimensions and properties, meeting demanding specifications for industries ranging from electronics and medical devices to motors and textiles.

But the reverse is just as true. Excessive tension can deform or fracture the material, compromising electrical performance or structural stability. Insufficient tension breeds slack windings, leading to uneven layering, signal interference, or mechanical weakness. Even small fluctuations in tension during the winding cycle can introduce invisible defects. The ones that only become catastrophic when the final product is tested or deployed in the field.

The Pursuit of Control

Controlling tension used to be an art entrusted to skilled operators. They’d adjust pulleys, monitor the feel of the wire, and make incremental corrections by experience. While this hands-on approach worked in low-volume environments, it proved unreliable at scale and left room for costly inconsistency. As manufacturing demands grew, automation stepped in, bringing sensor-driven feedback loops and programmable controls to the heart of the winding process.

Today’s best winding machines employ sophisticated tension control systems, many using closed-loop mechanisms that monitor wire stress in real time. These systems instantly make micro-adjustments as the dynamics of winding shift, whether due to material variability, changing speed, or bobbin shape. Hysteresis brakes, tensioners, and integrated servo controls translate precise data into exact actions, keeping tension within ideal thresholds and safeguarding long-term quality.

With automation, every coil is wound as reliably at the thousandth piece as the first, ensuring predictable performance and minimizing the risk of human error. Most advanced systems now enable operators to set profiles for different materials, wire gauges, and product specs. This makes high-volume production flexible, repeatable, and highly controlled.

The Connection to End-Product Performance

Tension is not just an input parameter. It’s an active factor that shapes a product’s capabilities. In motor and transformer winding, stable tension yields coils with ideal electrical inductance, resistance, and capacitance. Such uniformity prevents hotspots, improves heat dissipation, and ensures smooth functioning under demanding loads. In yarn winding or textile production, good tension control guarantees uniform dye uptake and mechanical integrity, reducing the risk of defects during subsequent processing.

The benefits translate directly into real-world reliability. Products wound with fluctuating tension may show poor electrical performance, increased noise or vibration, and reduced lifespan. On the other hand, tight tension control delivers components that function smoothly, resist environmental stresses, and uphold brand reputation through consistent quality.

The Cost of Inconsistency

Manufacturers know that tension troubles can be costly. Over-tensioned coils lead to unnecessary breaks, material waste, and additional downtime while machines are rethreaded. Under-tensioning, meanwhile, causes loose windings that may require manual correction, increase scrap rates, or pass undetected until field failures arise. Either scenario erodes efficiency, drives up operational costs, and tests the patience of quality assurance teams.

The solution is control, making tension as repeatable and manageable as any other line variable. Top-tier winding machines now allow for dynamic tension setting, adapting instantly to changing production needs. Real-time monitors flag deviations instantly, letting teams address issues before rejects accumulate or critical thresholds are breached.

Innovations in Tension Control: Raising the Standard

Recent advances in winding machine technology have redefined what manufacturers can expect from tension control. Closed-loop feedback systems fed by high-precision sensors, programmable tension profiles for diverse material types, and AI-driven analytics are recasting the possibilities for quality and performance. Machines can now account for temperature, material elasticity, and real-time process feedback during every winding cycle.

Some systems even log tension data for every part manufactured, enabling end-to-end traceability and deeper insights into process improvement. Automated maintenance checks and predictive diagnostics alert teams when mechanical wear might impact tension control, to promote consistent output and reducing surprise breakdowns.

Looking Ahead

As industries push for higher-performing products with greater consistency, tension control is positioned center stage in the quest for manufacturing excellence. It’s not simply a matter of following best practices, but of embracing innovation that enhances every aspect of production. Starting from speed and throughput to product reliability and after-sales maintenance.

Tomorrow’s winding machines will leverage smarter sensors, deeper analytics, and more adaptive control systems, delivering not only the uniformity manufacturers crave but also the quality demanded by the customers. The invisible thread of tension may never be seen by the end user, but its influence will be felt in every reliable start-up, in every silent coil, and in every product that withstands the test of time.

Conclusion

Even as winding machine technology evolves and automation becomes ubiquitous, tension control remains the defining factor separating good from great, average from exceptional. Mastering tension means mastering quality, uniformity, control, and performance. This makes winding machine technology the silent superpower of manufacturing’s most critical coils and components. In the relentless pursuit of excellence, those who understand the significance of tension will always hold the key to holding it all together.