Engineering Efficiency: Advanced Winding Machines in the Automotive World

A New Era for Automotive Manufacturing

The automotive industry is currently undergoing its biggest shift in decades, with electrification, intelligent safety systems, and lightweight platforms redefining what vehicles can do. Beneath the visible innovations, the hidden but obvious technologies are quietly aiding to this transformation. Advanced winding machines are among the most important tools that is enabling this revolutionary transformation.

These advanced machines deliver the precision, repeatability, and speed required to manufacture high‑performance motors, generators, actuators, and electronics. These machines are one of the important aspects that keep modern vehicles efficient, safe, and reliable. As manufacturers race to meet new expectations, winding systems have moved from being just another production tool to becoming strategic assets that directly shape vehicle performance and programme profitability.

Winding at the Heart of Automotive Technology

Electric traction motors, starter‑generators, pumps, fans, steering systems, and countless actuators all rely on carefully wound coils and stators to perform consistently over millions of duty cycles. In internal combustion and hybrid platforms, winding quality still dictates how reliably alternators, ignition systems, and auxiliary drives operate, while in fully electric vehicles it strongly influences driving range, torque response, and acoustic comfort. To keep pace with increasingly compact designs and higher power densities, automotive manufacturing needs coils and stators with tighter tolerances. This enables better thermal behaviour, and lower electrical losses than earlier generations could achieve.

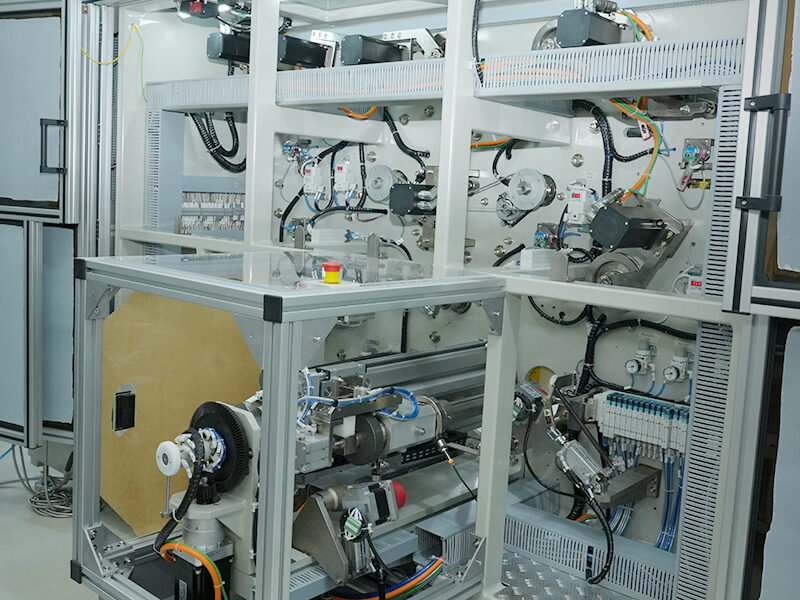

Modern stator and coil winding machines address these demands by combining CNC motion, servo control, and intelligent tension management to control each turn of wire with extreme accuracy. There was a time when manual or semi‑automatic processes once struggled with consistency. On the flip side, today’s equipment creates repeatable winding patterns that match digital design intent, enabling more ambitious motor concepts and long‑term stability in the field.

From Manual Limits to Advanced Machines

Traditional winding approaches in the automotive space often relied on skilled operators and mechanically driven equipment. However, this came with limited scalability and introduced human variability. As volumes climbed and designs grew more complex, especially for BLDC and multi‑pole stators, these methods became bottlenecks. They will constrain capacity and make it harder to maintain uniform quality across plants and regions. Advanced winding machines solve these challenges by automating wire placement, slot filling, tap handling, lead forming, and cutting through programmable, servo‑actuated mechanisms.

By digitising the process, manufacturers can shift quickly between motor variants or customer platforms. This paves way for loading new recipes rather than re‑engineering fixtures from scratch. This flexibility aligns with modern automotive product strategies, where platforms must support multiple trims, power levels, and regional requirements without escalating tooling cost or line complexity.

Precision as a Performance Multiplier

Coil geometry and stator layout have a direct impact on torque ripple, efficiency, heat generation, and noise in automotive electric machines. Minor inconsistencies in slot fill, wire distribution, or end‑turn shape can cause increased losses, hotspots, or vibration, eroding the benefits of sophisticated motor designs. Advanced winding systems use closed‑loop tension control, high‑resolution encoders, and real‑time monitoring to maintain optimal wire placement and density in every slot.

This precision enables engineers to deploy higher slot fill factors and more aggressive magnetic designs without sacrificing robustness. This process results in motors that are smaller, lighter, and more efficient yet capable of handling demanding automotive duty cycles. For OEMs, that translates into improved fuel economy or EV range, smoother driveability, and quieter cabins. These are the differentiators that are proving increasingly crucial in a crowded marketplace.

Efficiency Gains Across the Production Line

Beyond product performance, advanced winding machines significantly boost manufacturing efficiency by increasing throughput and reducing waste. Automated loading, multi‑station indexing, and simultaneous multi‑coil winding allow a single machine to produce far more stators or coils per shift than legacy equipment, often while using fewer operators. Integrated error‑proofing sensors and in‑cycle inspection reduce rework and scrap, ensuring that more parts meet specification on the first pass.

These machines also support lean manufacturing initiatives by minimising material overuse and standardising processes across plants. Features such as programmable wire usage, optimised trajectory planning, and intelligent tap handling help conserve copper and insulation. This is very critical as raw‑material prices fluctuate, and sustainability expectations grow. When connected to MES or plant analytics platforms, advanced winders become data sources for continuous improvement, feeding utilisation, quality, and downtime metrics back into operational decision‑making.

Enabling the Electric and Software‑Defined Vehicle

The shift toward battery‑electric and software‑defined vehicles increases the importance of high‑quality winding tremendously. Electric drivetrains require multiple motors like traction, auxiliaries, and thermal management. Every single aspect comes with different duty cycles and form factors, but all needing robust, high‑efficiency coils and stators. Advanced machines made for EV stators, hairpin concepts, or needle‑wound configurations make it practical to scale production of these designs while preserving the fidelity of complex winding schemes.

As vehicles incorporate more mechatronic subsystems and drive‑by‑wire functionality, the number of electromagnetic components grows too, extending the role of precise winding into steering, braking, chassis control, and advanced driver‑assistance systems. By ensuring consistent, high‑volume output of dependable components, advanced winding equipment becomes a foundational enabler for safe and responsive automation on the road.

Innovation at the Core of Automotive Winding

Future generations of advanced machines are likely to deepen their integration with AI, machine vision, and connected factory platforms, further enhancing efficiency and quality in automotive winding lines. Self‑optimising processes that adjust parameters based on live feedback from torque, loss, or NVH measurements will tighten the loop between design and production. Modular and reconfigurable architectures will make it easier to launch new motor families or adapt capacity as vehicle programmes evolve.

Conclusion

For automotive manufacturers and tier suppliers, investment in advanced winding technology is no longer a niche consideration; it is a strategic lever for delivering competitive, high‑performance vehicles at scale. By combining precision, automation, and data‑driven control, these machines are reshaping not just how motors and coils are made, but what the automotive industry can achieve in the next decade of electrification and intelligent mobility.