Custom Winding Solutions for Space-grade Electronics and Components

In the vast expanse of space exploration, where every gram counts, the reliability of electronic components becomes paramount.

Space-grade electronics must endure extreme temperatures, radiation, vacuum conditions, and relentless vibrations.

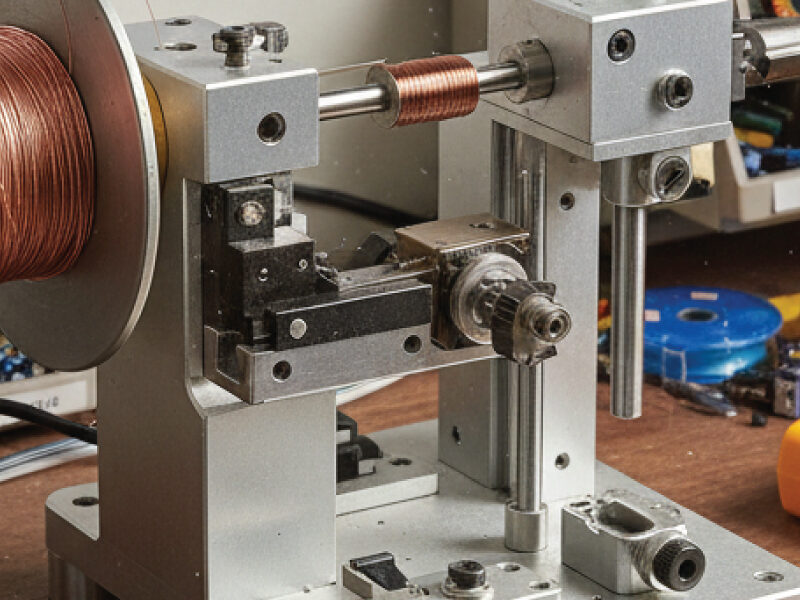

At the heart of many such systems lie custom winding solutions: precision-engineered coils, transformers, and inductors tailored to meet the stringent demands of aerospace applications. These aren’t off-the-shelf parts; they’re bespoke designs that ensure signal integrity, power efficiency, and operational longevity in the unforgiving environment of space.

Understanding Space-Grade Electronics and the Need for Customization

Space-grade electronics refer to components qualified to operate in the harsh conditions of space, adhering to standards like those from NASA, ESA, or MIL-STD specifications.

Unlike commercial-grade parts, these must survive radiation-induced degradation, thermal cycling from -150°C to +125°C, and electromagnetic interference without compromising performance. Transformers, inductors, and solenoids rely on winding technologies to manage magnetic fields and electrical currents effectively.

Why custom windings?

Standard components often fall short in space due to size constraints, weight limitations, and the need for radiation hardness. For instance, a satellite’s power converter might require an inductor that minimizes electromagnetic emissions to avoid interfering with sensitive instruments.

Off-the-shelf options could introduce unwanted noise or fail under cosmic ray bombardment. Custom winding solutions address these by starting from the ground up: engineers design wire gauges, core materials, and layering techniques based on specific mission parameters.

Consider the CubeSat revolution, where small satellites demand compacts yet robust electronics. A custom-wound transformer might use high-temperature superconducting wires to reduce losses in a footprint.

This level of tailoring not only enhances reliability but also optimizes resource use, making space missions more cost-effective. Custom windings bridge the gap between theoretical design and practical endurance, ensuring that electronics don’t just survive space; they thrive in it.

Key Technologies and Materials in Custom Winding

Crafting windings for space-grade applications involves advanced materials and precision manufacturing.

Traditional copper wires:

Traditional copper wires give way to alternatives like silver-plated or gold-alloy conductors for superior conductivity and corrosion resistance. Cores often incorporate ferrites, amorphous metals, or even nanomaterials to handle high frequencies without saturation.

For radiation-prone environments, shielding layers of mu-metal or specialized polymers prevent single-event upsets (SEUs) that could flip bits in digital circuits.

The winding process itself is a marvel of engineering. Techniques like multilayer orthogonal winding or toroidal configurations allow for compact designs with low parasitic capacitance.

Computer-aided design

Computer-aided design (CAD) software simulates magnetic flux and thermal behavior, iterating designs virtually before production. Additive manufacturing, or 3D printing, is emerging as a game-changer, enabling intricate geometries that traditional bobbin winding can’t achieve.

Quality assurance is non-negotiable. Each custom winding undergoes environmental testing: thermal vacuum chambers mimic orbital conditions, while radiation simulators bombard samples with protons and heavy ions.

Certifications like AS9100 ensure compliance with aerospace standards. These technologies don’t just build components; they forge reliability into every turn of the wire, convincing stakeholders that investing in custom solutions yields dividends in mission uptime and data integrity.

Challenges in Developing Custom Winding Solutions

Despite their advantages, custom windings for space face formidable hurdles.

Balance performance

The primary challenge is balancing performance with mass. Spacecraft launch costs can exceed $10,000 per kilogram, so even minor weight savings matter. Engineers must optimize wire density without increasing vulnerability to micro-vibrations. This can cause fatigue in solder joints.

Radiation hardness remains a persistent issue. Cosmic rays can induce currents in windings, leading to overheating or data corruption. Mitigating this requires exotic materials like tantalum-based dielectrics, which are expensive and hard to source. Supply chain disruptions further complicate matters.

Scalability poses another dilemma. While custom designs excel for low-volume, high-stakes missions like Mars rovers, producing them at scale for constellations like Starlink demands hybrid approaches: modular windings that can be semi-customized.

Testing regimes are rigorous and time-intensive; a single qualification run can take months, delaying projects. Yet, these challenges underscore the value of expertise. Partnering with specialized manufacturers who navigate these pitfalls ensures that custom windings not only meet but exceed expectations, turning potential roadblocks into competitive edges.

Real-World Applications

Custom winding solutions power some of humanity’s boldest endeavours.

NASA Artemis program

In NASA’s Artemis program, custom inductors in the Orion spacecraft’s power distribution system manage high-voltage DC-DC conversion under lunar radiation. These windings, designed with graphene-enhanced cores, reduce energy losses by 20%, extending battery life during critical manoeuvres.

The James Webb Space Telescope

The James Webb Space Telescope (JWST) exemplifies precision. Its cryogenic instruments rely on custom transformers wound with low-thermal-expansion alloys to maintain superconductivity at near-absolute zero. This design prevented signal drift, enabling the telescope’s stunning infrared images of distant galaxies.

SpaceX Falcon Rockets

In the commercial sector, SpaceX’s Falcon rockets incorporate custom solenoids for attitude control thrusters, where rapid response times are achieved through bifilar winding techniques

The Future of Custom Winding in Space Exploration

Looking ahead, custom winding solutions are poised for transformation, driven by advancements in AI, nanotechnology, and sustainable manufacturing.

AI-optimized design tools will predict winding failures pre-emptively, slashing development cycles from years to months. Imagine neural networks generating coil topologies that self-heal under radiation, using embedded smart materials.

Sustainability is gaining traction too. With space debris a growing concern, recyclable windings from bio-based polymers could reduce end-of-life waste for deorbiting satellites.

Miniaturization will accelerate via MEMS (micro-electro-mechanical systems), integrating windings directly into chips for pico-satellites. Quantum computing’s rise may demand ultra-low-noise inductors, pushing materials science toward room-temperature superconductors.

Global collaborations, like those under the International Space Station framework, will standardize custom winding specs, fostering interoperability. As private ventures like Blue Origin and Virgin Galactic proliferate, demand for affordable custom solutions will surge, democratizing access. This evolution promises a future where space-grade electronics are not just robust but adaptive, engaging a new generation of innovators to push boundaries further.

Conclusion

custom winding solutions stand as unsung heroes in space-grade electronics, delivering the precision and resilience needed for extraordinary missions.

From overcoming material challenges to enabling groundbreaking applications, they embody the ingenuity required to conquer the cosmos.

As space exploration expands, embracing these technologies will be key to unlocking its full potential. This ensures that our electronic companions in the stars perform flawlessly, time and again.