Connected Coils: IoT Integration in Winding Machine Operations

Introduction

The manufacturing floor has always been noisy with the sound of motors and the rhythm of production. However, all the voices were human. This scenario is gradually shifting in recent times. Machines are speaking to each other, exchanging data, diagnosing themselves, and optimizing processes without human intervention. This is the promise of the Internet of Things (IoT). It is a network of interconnected devices that transforms winding machines from isolated assets into intelligent contributors within a smart manufacturing ecosystem.

With real-time data streaming from sensors, actuators, and controllers, manufacturers gain unprecedented visibility into every turn of wire, every coil formed, and every performance metric that matters. The result is not just automation, but adaptive, intelligent production that responds instantly to changing conditions.

The Rise of IoT in Winding Machine Operations

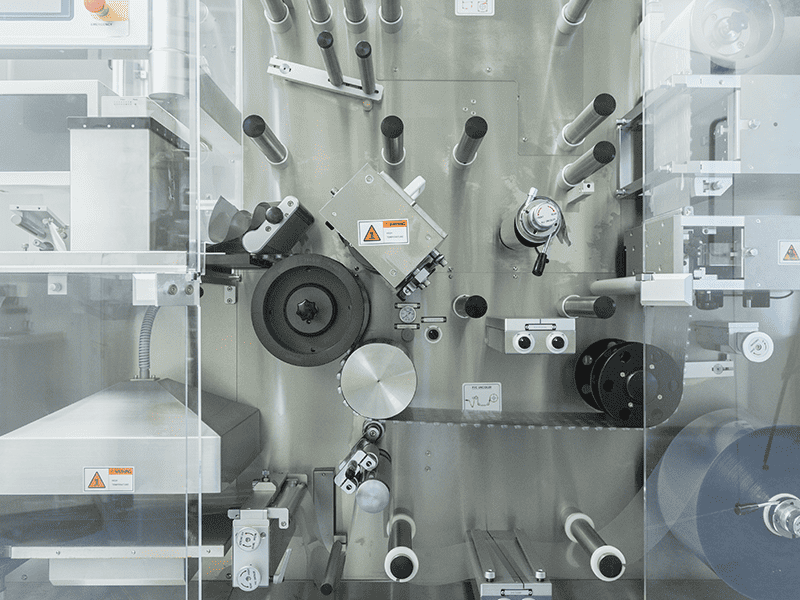

IoT has fundamentally changed how winding machines operate and how manufacturers manage them. At its core, IoT involves embedding sensors and communication modules directly into winding equipment, enabling continuous monitoring of critical parameters such as wire tension, spindle speed, temperature, vibration, and power consumption. This data is collected in real time and transmitted to centralized platforms where it can be analysed, visualized, and acted upon. Unlike traditional systems that rely on periodic inspections or manual data logging, IoT-enabled winding machines provide a constant stream of actionable intelligence, empowering operators and managers to make informed decisions instantly.

The integration of IoT technology extends beyond individual machines to entire production lines. When multiple winding machines communicate with each other and with upstream and downstream processes, manufacturers achieve synchronized workflows that minimize bottlenecks and maximize throughput. Connectivity becomes the backbone of operational excellence, linking shop floor equipment with enterprise resource planning systems, manufacturing execution systems, and cloud-based analytics platforms. This interconnected environment enables manufacturers to track production in real time, adjust schedules dynamically, and respond proactively to quality issues or equipment failures.

The Foundation of Smart Decision-Making

The value of IoT in winding operations hinges on its ability to deliver real-time data at scale. Traditional manufacturing relied on delayed reporting, with quality checks and performance reviews conducted hours or days after production. IoT changes this scenario by making every machine a source of immediate insight. Sensors embedded in winding machines capture data points at millisecond intervals, monitoring everything from coil geometry to insulation quality. This continuous feedback loop allows for instant detection of deviations, enabling corrective actions before defects propagate through the production batch.

Real-time data also empowers predictive maintenance strategies that were previously impossible. By analysing vibration patterns, temperature trends, and operational anomalies, IoT systems can forecast equipment failures with remarkable accuracy. Maintenance teams receive advance warnings when components show signs of wear, allowing them to schedule repairs during planned downtime rather than responding to unexpected breakdowns. This proactive approach reduces unplanned outages, extends equipment lifespan, and minimizes the costs associated with emergency repairs and production disruptions.

Building Interconnected Production Ecosystems

Smart manufacturing represents the convergence of IoT, automation, artificial intelligence, and data analytics into cohesive production systems. In winding operations, this means machines that don’t just execute programmed sequences but actively optimize their performance based on live conditions. IoT-enabled winding machines can automatically adjust tension profiles when detecting variations in wire diameter, modify layering strategies to compensate for temperature fluctuations, and communicate with quality control systems to flag potential issues instantly.

The integration of digital twins and virtual replicas of physical winding machines takes smart manufacturing to the next level. Engineers can simulate production scenarios, test new winding patterns, and optimize parameters in a virtual environment before implementing changes on the factory floor. Digital twins continuously sync with their physical counterparts via IoT connectivity, providing real-time visibility into machine health, performance trends, and production quality. This capability accelerates innovation, reduces trial-and-error cycles, and enables manufacturers to respond quickly to market demands or customer specifications.

Automation Enhanced by Connectivity

While automation has long been a cornerstone of winding machine operations, IoT integration elevates it to new heights. Traditional automation systems execute pre-programmed routines with limited adaptability. IoT-connected machines leverage continuous data streams to refine their operations dynamically. For example, when sensors detect a shift in material properties or environmental conditions, the system can automatically recalibrate winding parameters to maintain consistent quality. This adaptive automation reduces waste, improves yield, and minimizes the need for manual interventions.

Connectivity also enables remote operation and management of winding machines. Plant managers can monitor production from anywhere in the world, adjusting settings, troubleshooting issues, and accessing performance dashboards through secure cloud platforms. Remote diagnostics allow expert technicians to identify problems and guide on-site personnel through corrective procedures without traveling to the facility. This capability is particularly valuable for manufacturers operating multiple sites or serving global markets, as it ensures consistent performance standards and rapid response to operational challenges.

Driving Efficiency Through Data-Driven Insights

The goal of IoT integration is to drive measurable improvements in efficiency across all aspects of winding operations. Real-time monitoring and analytics provide manufacturers with granular insights into resource utilization, energy consumption, and production bottlenecks. By identifying inefficiencies and optimizing workflows, IoT systems help reduce cycle times, lower operating costs, and increase overall equipment effectiveness. Data-driven decision-making replaces intuition and guesswork, enabling managers to allocate resources more effectively and prioritize initiatives that deliver the greatest return on investment.

IoT also enhances supply chain visibility and inventory management. Connected winding machines can automatically track material consumption, trigger replenishment orders when supplies run low, and coordinate with logistics systems to ensure timely delivery of components. This level of integration minimizes production delays caused by material shortages and reduces excess inventory that ties up working capital. Furthermore, comprehensive data logging provides complete traceability for every coil produced, supporting quality assurance, regulatory compliance, and customer confidence.

Real-World Applications

Leading manufacturers across automotive, electronics, and energy sectors have already realized substantial benefits from IoT-enabled winding technology. Companies report productivity gains of twenty to thirty percent after implementing connected systems with real-time monitoring and predictive maintenance capabilities. One textile manufacturer improved spindle reliability by nineteen percent through AI and IoT sensor integration, while an electronics producer reduced manufacturing waste by seventeen percent per batch using adaptive control algorithms.

In high-mix production environments, IoT connectivity enables rapid changeovers and flexible manufacturing. Winding machines automatically load new recipes, adjust parameters, and reconfigure tooling based on incoming orders, all without manual programming. This agility allows manufacturers to serve diverse customer requirements efficiently, supporting mass customization and just-in-time production strategies that were previously impractical.

Challenges and Considerations

While the benefits of IoT integration are compelling, successful implementation requires careful planning and execution. Manufacturers must address challenges related to data security, system interoperability, and organizational change management. Ensuring that IoT devices and networks are protected against cybersecurity threats is paramount, as connected systems can become vulnerable entry points for malicious actors. Robust encryption, access controls, and regular security audits are essential components of any IoT deployment.

Interoperability is another critical consideration. Winding machines from different manufacturers may use proprietary communication protocols, making integration complex. Adopting open standards and leveraging middleware platforms can help bridge these gaps, enabling seamless data exchange across diverse equipment and software systems. Additionally, successful IoT initiatives require workforce training and cultural adaptation, as employees transition from traditional practices to data-driven operations.

Conclusion

The integration of IoT in winding machine operations represents a fundamental shift in how manufacturers approach production. By enabling real-time data collection, intelligent automation, and seamless connectivity, IoT transforms winding machines into strategic assets within smart manufacturing ecosystems. The benefits position manufacturers for sustained competitive advantage in an increasingly demanding market.

As IoT technologies continue evolving, the potential for innovation in winding operations will only expand. Manufacturers who embrace connectivity today are building the foundation for tomorrow’s intelligent factories, where data-driven insights and adaptive automation define success.