CNC Winding Machines: Advantages Over Traditional Winding Methods

Introduction

Imagine standing on the edge of tradition, peering into a future where machines do more than just repeat human motions. They are expanding what was once thought possible. In the world of winding, CNC technologies don’t merely automate. They redefine the boundaries of speed, complexity, and exactitude. Where yesterday’s methods relied on intuition and hard-earned experience, today’s CNC winding machines translate digital blueprints into real-world perfection, every time.

What’s most transformative isn’t just the switch from manual to automated, but the mindset shift. From accepting variation to insisting on precision, from settling for efficiency gains to demanding cost breakthroughs, and from reacting to errors to preventing them altogether. CNC winding has become the catalyst for a new manufacturing ethos, where the only limit is imagination and every coil carries the mark of innovation engineered for tomorrow’s challenges.

Why Automation Matters?

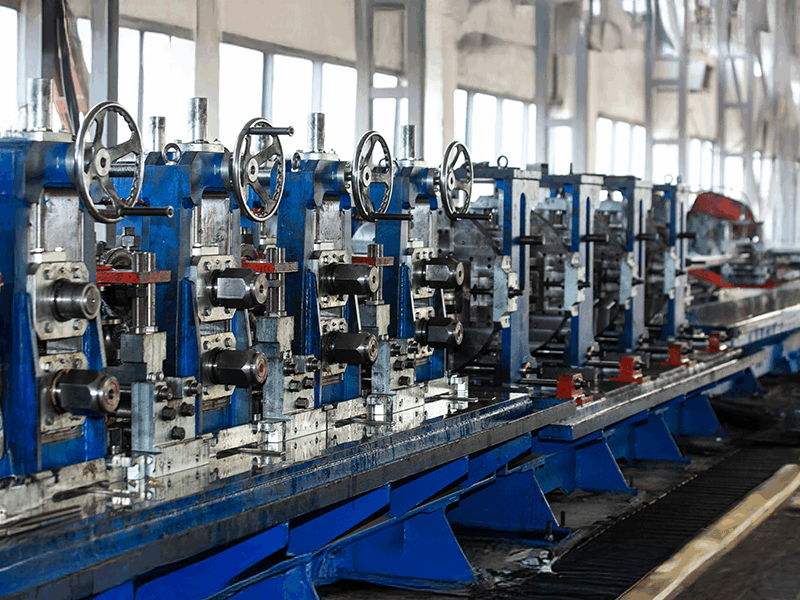

For years, traditional winding methods relied on skilled operators to guide wires around cores, adjust patterns by eye, and maintain tension through experience and touch. These manual systems often meant significant time investments, variable results, and repeated recalibration. While they served industries well, the margin for human error was ever-present, and speed came at the expense of consistency.

Enter CNC (Computer Numerical Control) winding machines, automated systems programmed to execute complex winding routines with mathematical exactitude. Their arrival marked a seismic shift in production philosophy. Instead of relying on manual dexterity and continuous intervention, manufacturers could now embed precise instructions into the machine’s brain and trust it to execute relentlessly and consistently, no matter the shift, the operator, or the order size.

Accuracy: The Currency of Modern Manufacturing

Nothing showcases the strength of CNC winding machines like their unyielding commitment to precision. With digital controls and closed-loop feedback systems, these machines deliver winding patterns, wire placement, and tension management with repeatability that is simply unattainable by hand. When a blueprint calls for a coil wound to microns of tolerance, even on intricate or asymmetrical cores, CNC machines rise without effort.

This level of accuracy isn’t just a technical boast. It’s fundamental for applications ranging from aerospace to medical devices, power electronics to smart sensors. Tighter tolerances mean better electrical performance, lower incidence of failure, and direct compliance with the strictest global standards. Creating products manufacturers can stand behind and customers can trust.

Efficiency—From Setup to Scale

Beyond accuracy, CNC automation unlocks new realms of efficiency. Where manual winding demanded experienced operators, tedious changeovers, and slow ramp-up for new product lines, CNC winding machines thrive on versatility and speed. Tooling changes and programming updates are performed digitally in minutes, not hours. Production cycles accelerate as processes are optimized and replicated across machines, regardless of operator skill.

Advanced CNC platforms also support multi-spindle configurations, high-speed winding, and real-time detection of anomalies. This means more coils produced in less time, with less downtime and fewer rejected parts. For manufacturers facing tight lead times, fluctuating orders, or a need to scale production overnight, CNC automation is the master key to operational agility.

Rethinking Investment and Payback

An enduring myth is that automation, especially CNC, commands a prohibitive upfront cost. CNC winding machines are widely recognized for delivering substantial long-term savings. Labour requirements drop as machines handle more processes with minimal supervision. Out-of-spec parts, expensive rework, and waste are dramatically reduced through built-in quality assurance.

Downtime shrinks, thanks to predictive maintenance alerts and quick programming turnovers. No waiting for highly specialized staff to be available for every batch run. Energy usage is often optimized, as CNC systems wind exactly what’s needed, when it’s needed, with little surplus or scrap. The result is a clear path to lower operational costs, faster ROI, and stronger margins, especially when production demands fluctuate or strict quality is mandatory.

Automation: Beyond a Buzzword

The heart of CNC winding machines is automation, but it’s not just a matter of pushing start and stepping back. Today’s machines operate within smart factories, communicating data to central systems, receiving automatic recipe updates, and streamlining production across multiple product families. Integrated sensors and intelligent software re-calibrate setups mid-cycle, maintain ideal winding tension, and even learn from previous runs to further improve future performance.

Automation also means flexibility. Manufacturers can run small custom batches beside mass-production orders, switch wire types with ease, and respond to urgent requests quickly. Automation transforms the winding floor from a bottleneck into a dynamic engine of innovation, supporting everything from prototyping to full-scale manufacturing runs with equal grace.

Comparing CNC vs Manual Winding

When viewed side-by-side, CNC platforms outperform traditional winding methods in almost every aspect. Manual stations, though valuable for unique and artisan work cannot match the volume, precision, or cost control that CNC delivers for modern industrial demands. Repetitive tasks shift from skilled labourers to machines programmed for infinite repeatability. Quality control moves from subjective to objective, with every winding digitally measured and logged.

The shift isn’t limited to coil geometry or production volumes; it’s an organizational change. Engineers can focus on process development and innovation rather than hand-holding the production line. Operations managers gain confidence in scheduling and order fulfilment. Procurement and finance teams see clear reductions in waste and labour costs. Customers receive consistent, high-performance components, batch after batch.

The Future of CNC Winding Machines

As manufacturing evolves to demand smaller footprints, higher speeds, and smarter systems, CNC winding machines will continue to set the benchmark for innovation. New advancements in artificial intelligence, real-time process optimization, and material science will extend the reach of CNC, enabling smarter coils for next-generation technology.

Soon, the lines between design, prototyping, and manufacturing will blur even further. With CNC automation, what’s imagined on a screen can be realized in physical form in minutes, tested, refined, and productionized with minimal risk and maximum precision. The era of waiting on experience to overcome variability is fading; in its place stands a future built on certainty, speed, and intelligent engineering.

Conclusion

The transition from traditional winding to CNC isn’t just technological, it’s cultural. By embracing the benefits of automation, manufacturers unlock explosive gains in accuracy, cost savings, and efficiency. CNC winding machines become not just tools, but strategic partners in the race for global competitiveness. As the world of manufacturing presses forward, one thing becomes clear: precision, scalability, and intelligent automation are not just advantages, they are expectations. CNC winding machines deliver on all fronts, empowering manufacturers to meet the needs of today and tomorrow, wire by wire, revolution by revolution.