The New Backbone: Winding Machines and Robotics Manufacturing

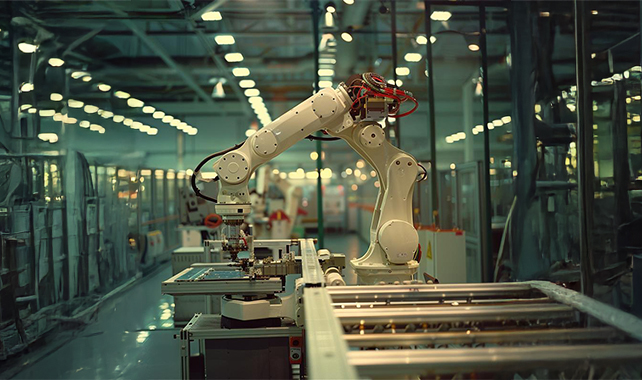

The Dawn of a Smarter Factory

In the competitive world of advanced robotics, innovation is driven by a relentless pursuit of precision and automation. Robotic arms, motors that deliver torque at micro and macro scales, and sensors that communicate in real time depend on components built with breathtaking consistency. At the very heart of these foundational parts are the latest generation of winding machines. As robotics evolves toward more complex, adaptive, and efficient systems, the technology behind electromagnetic coil production is quietly shaping the future, setting new benchmarks for quality, speed, and functionality.

Winding Machines: Where Robotics Manufacturing Begins

Any robot, from industrial assembly bots to medical instruments and autonomous vehicles, is only as good as its actuation and sensing elements. At the heart of these systems lie finely wound coils and stators that translate digital commands into kinetic motion. High-tech winding machines use sophisticated controls and smart algorithms to automate the process of wrapping copper or other conductive wires around precise forms. These controls include creating the electromagnets and sensors that give robots their core abilities to move, sense, and respond.

Modern winding machines are built for precision in every sense. Computerized tension control, multi-axis guidance systems, and real-time feedback enable flawless layering of wire. This eliminates inconsistencies that could compromise a robot’s motor efficiency or result in performance drift over time. As the demand for compact, energy-efficient robotic systems grows, the ability to miniaturize windings while maintaining tight tolerances becomes an absolute necessity. This is a feature that only cutting-edge winding machines can deliver.

Precision Engineering Powers Robotic Progress

The reliability and versatility of a robot is directly linked to the consistency and accuracy of its internal windings. Even microscopic deviations in coil density, layer height, or wire path can cause heat buildup, signal loss, or movement errors in servo motors and actuators. Here, winding machines do what manual methods cannot. They maintain control over every parameter, using digital blueprints and integrated quality checks to achieve target specifications repeatedly.

In sectors like medical robotics, where safety is important, or aerospace, where weight and power efficiency rule, winding precision is a non-negotiable requirement. High-performance machines now incorporate automated inspection systems, checking insulation resistance, physical geometry, and electrical continuity as coils are processed. This results in motors, solenoids, and sensors that are not only more powerful, but also longer lasting and less prone to field failures.

Automation: Bringing Scale and Flexibility to Robotics

Automation in winding is a game-changer for robotics manufacturers. Instead of relying on skilled technicians for slow, labour-intensive wire placement, advanced winding machines operate continuously with minimal supervision, supporting high-volume production and custom batch runs alike. Intelligent control software allows manufacturers to shift seamlessly between different coil sizes, materials, and geometries without lengthy retooling. Flexible feeders, programmable spindle movements, and adaptive fixtures have made it possible to bind even the most intricate coil forms and multi-layer arrangements with exceptional repeatability.

This automation is not just about speed. It’s about unlocking scalable, cost-effective production as robotics demand skyrockets. With predictive maintenance features and IoT-enabled data collection, the newest winding machines minimize downtime, reduce error rates, and give plant managers real-time insights into efficiency and potential process improvements. For a sector racing to serve diverse applications, this agility is key to getting robots from concept to deployment at record pace.

Materials, Miniaturization, and Smart Manufacturing

Tomorrow’s robots will be lighter, faster, smarter, and more interconnected than ever before. They are driven in part by advances in both the components they use and the machines that create them. Today’s winding machines are built to handle ultra-fine wires, new conductive alloys, and high-performance insulation required for miniaturized or high-frequency coils. In collaborative robotics and medical wearables, for example, the ability to create extremely small, robust windings enables new product geometries and applications that were previously unattainable.

Smart manufacturing features such as automated tool changers, digital twins for process simulation, and cloud-based production management allow winding machines to keep pace with new robotics demands. Manufacturers can now quickly prototype custom windings, ramp up pilot runs, and launch full production, all while maintaining traceability and compliance with rigorous industry standards. Real-time quality data and closed-loop control mean that every coil is not only made to spec, but its production history is fully auditable. This is a critical consideration for high-reliability robots used in safety-critical roles.

Robotics Manufacturing Gets Personal

The era of one-size-fits-all robots is fading, as manufacturers are increasingly called upon to produce application-specific, highly customized robotic solutions. Winding machines have adapted to this trend through modular design, advanced software, and adaptability for quick job changes. Modern systems can interpret CAD/CAM files or networked commands, configuring themselves to deliver unique windings for a particular motor or sensor within minutes. This type of mass customization is made possible only through the combination of precision mechanics and smart automation, driving new business models and opening the door to robotics for niches across medicine, agriculture, logistics, and beyond.

For manufacturers, this flexibility means new revenue streams and the ability to meet short lead times. For robotics end-users, the result is a new generation of machines whether humanoid arms, inspection drones, or surgical robots, each perfectly engineered for its job.

The Synergy of Robotics and Precision Winding

As robotics manufacturing continues its rapid evolution, the role of the winding machine will only grow in strategic importance. The next wave of innovation is likely to include even greater integration of AI, machine learning for predictive quality, and advanced materials that require ultra-precise placement. Expect to see fully digital, connected winding stations working in concert with robotic assembly cells, all feeding data upward to give insight, feedback, and continual process improvement. These capabilities not only support higher performance in robots themselves but also deliver better manufacturing economics. They give exceptional outcomes using less energy and raw material per finished part, with zero compromise on precision or function.

Conclusion

Robotics is among the most dynamic frontiers of modern manufacturing, and its meteoric rise is powered literally and figuratively. It is powered by the precision output of advanced winding machines. From boosting energy efficiency to fuelling miniaturization, from ensuring repeatability to enabling rapid customization, these machines are laying the foundation for the next great leap in robotics. The partnership of automation, precision, and smart winding never stops pushing the boundaries of what’s possible. It guarantees that as robotics transform industry, the humble winding machine will remain one of its most critical architects.