Performance Unravelled: Comparing Manual and Automated Winding Machines

Introduction

Across the globe, manufacturing is undergoing a profound transformation defined by speed, accuracy, and relentless demands for improved productivity. In the world of coil, motor, and transformer production, the choice between manual and automated winding machines is at the core of this revolution.

For decades, manual winding has been celebrated for its flexibility and adaptability in handling small batches, prototypes, or specialized products. Yet as markets evolve and volumes surge, organizations must ask whether tradition holds up against the consistency and speed now offered by automated equipment. For those tasked with optimizing processes, the comparison is not just academic. It is essential to balancing cost, quality, and performance for every product line.

Manual Winding Machines

Manual winding machines remain trusted tools in workshops and prototyping labs. Their operation is straightforward, placing control directly in the hands of a skilled operator. With manual methods, wire tension, coil geometry, and traversal can be adjusted on the fly. It will be ideal for custom designs or specialized, low-volume runs. When unique configurations or artisanal quality are required, the human touch is often preferred.

However, manual winding’s greatest asset is also its main performance constraint. Operator fatigue, attention span, and physical dexterity inevitably introduce variability from unit to unit. Producing hundreds or thousands of identical coils in succession becomes not only physically demanding but also prone to errors such as uneven winding, crossovers, or inconsistent tension.

Quality control relies heavily on visual inspection and rework, both of which slow production. Thus, in environments where turnaround and output are paramount, productivity ceilings quickly become apparent. Manual machines do have a lower initial investment and are easier to maintain, but these savings can be eroded by longer cycle times, higher labour costs, and fluctuating yield rates for larger orders.

Raising the Bar for Consistency and Output

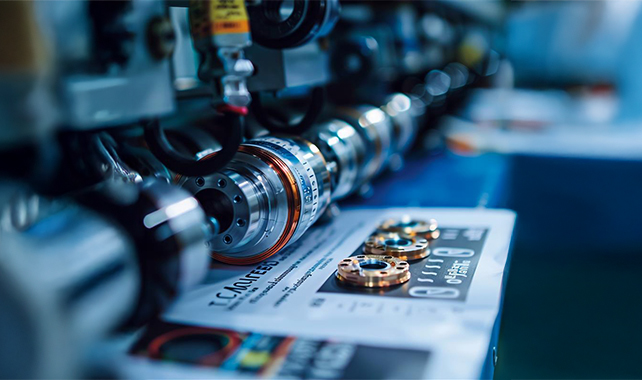

The past two decades has seen an explosion in the adoption of automated winding machines for everything from small electric motors to mass-market transformers. These systems use programmable logic controllers (PLCs), motorized spindles, and advanced sensor technology to keep wire tension, layer count, and winding geometry under precise control. The predictable, machine-driven process ensures every coil is produced within the same tight tolerance, hour after hour, batch after batch.

When it comes to performance, automated winding excels by delivering highly uniform results at speeds far beyond human capability. Automated equipment can execute multiple windings simultaneously, bring automatic error correction to the process, and generate live data for continuous process monitoring. With minimal operator intervention required, throughput soars while labour costs per product fall. Perhaps more importantly, automation reduces rework rates, limits scrap and bolsters the reputation of the manufacturer for delivering consistently high-quality goods on schedule.

Set-up times are streamlined with recipe-driven programming, allowing for rapid transitions between product SKUs or geometry changes. Where manual methods require retooling and calibration for every new coil type, automated machines can switch profiles at the push of a button. This will give users a scalable platform for both long and short runs.

Comparing Productivity and Efficiency

A true comparison of manual and automated winding machines centres on two critical aspects: productivity and efficiency. In side-by-side tests and manufacturing environments, automated machines routinely outperform manual processes by producing more units per hour and maintaining quality over extended shifts. Lead times for large orders are shortened dramatically, and bottlenecks associated with handwork or re-inspection are virtually eliminated.

Efficiency gains also show up in resource management. Automated winding uses wire and insulation materials with razor-sharp precision, dramatically reducing waste and maximizing the conversion of raw materials into finished products. Automated tension control and layer verification prevent common manual errors, further cutting costs associated with scrap and test failures. Maintenance routines for automated equipment, while sometimes more complex and requiring specialized knowledge, are balanced by longer service intervals and the availability of predictive diagnostics. This helps in further driving down lifetime operational costs.

Quality and Consistency: Where Automation Makes the Difference

In applications demanding tight coil tolerances, repeatability, and minimal variation such as automotive parts, medical devices, or advanced electronics demonstrate a consistent edge. Because every winding action is dictated by programming, deviations due to human error, fatigue, or oversight are nearly eliminated. Measurement systems and in-line quality feedback can catch deviations immediately, allowing only products meeting all specifications to move forward.

Manual systems, by contrast, are harder to audit and rely on operator skill to maintain uniformity. Even among highly trained workers, quality can drift as focus or energy wanes through long hours or batch runs. There is also greater variability if multiple operators are working on the same lot, making downstream standardization and customer confidence a recurring challenge.

Flexibility, Setup, and Adaptability

While automation dominates in high-volume and high-consistency environments, manual winding retains its place for unique, variable, or specialized projects. When a new design or niche model needs development, manual techniques allow fast iteration, hands-on problem-solving, and creative experiments that rigid automation might not accommodate. For small runs or repairs, manual methods can be more cost-effective, avoiding the programming and tooling investments of automated systems for every prototype.

However, advancements in automation are quickly closing this gap. Programmable machines now allow digital recipe storage, fast reconfiguration, and minimal downtime between jobs. Once prohibitively slow to set up for bespoke work, modern automated winders can now compete in flexibility, adapting not only to high throughput but also to frequent changeovers characteristic of custom manufacturing.

Training, Labour, and Workplace Impact

Transitioning from manual to automated solutions introduces new considerations around training and workforce development. Manual winding depends on easily taught, tactile skills; anyone with patience and practice can become proficient. Automated systems, however, demand technical literacy. Operators must understand programming, machine interfaces, and sometimes troubleshooting sensors or PLCs. While automation may streamline or reduce certain labour requirements, it opens roles for higher-level process supervision, equipment maintenance, and data-driven quality management.

For industries concerned about workforce displacement, the shift to automation often means upskilling existing teams and developing layered capabilities: skilled technicians to diagnose equipment, programmers to refine production recipes, and quality managers to respond to process analytics. Far from removing the need for human expertise, automation changes its focus by cantering people where they offer the greatest impact and using machines to take on the monotonous or ergonomically risky tasks.

Costs, Investment, and Return on Productivity

At first glance, manual winders win with their low up-front price and simple maintenance, appealing to budget-conscious firms or those entering new markets. However, when calculating total cost of ownership, productivity, and opportunity cost, automated systems quickly make their case. Faster cycles, greater consistency, less waste, and fewer labour hours per finished good mean that well-utilized automated winders pay for themselves in faster order fulfilment, higher sales, and lower warranty or rework expenses. Industries thriving on razor-thin margins or fast product launches increasingly choose automation to stay ahead.

Conclusion

The evolution from manual to automated winding is not a question of replacement, but of matching the right tool to the right business need. Manual machines remain valuable in creative, variable, and small-batch environments; automated winding is the reigning choice for scaling, standardizing, and competing in today’s demanding, high-volume markets. By weighing performance, productivity, consistency, and labour realities, manufacturers can harness the strengths of both approaches, ensuring that every coil produced meets the standards of tomorrow’s industry.