Pushing Performance: Design Challenges in High-Speed Winding Machines

Introduction

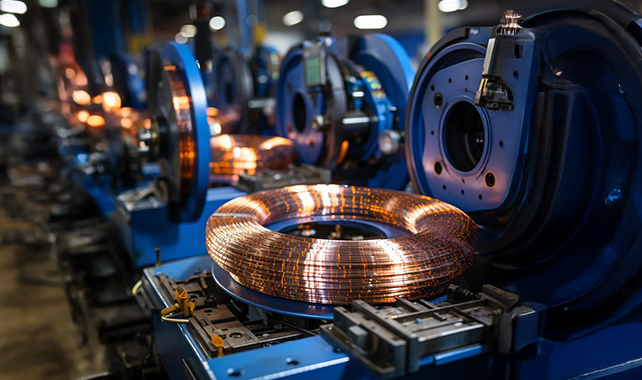

In a world where production timelines are shrinking and customer expectations are rising. High-speed winding machines have become essential to industries from electric vehicles and medicine to electronics and energy. But pushing winding machines to run faster is not a simple question of spinning parts harder or running longer hours. It unleashes a complex universe of design challenges including mechanical, electrical, thermal, and digital. These will test the boundaries of both engineering and material science. Designing the next generation of high-speed winding machines therefore demands a blend of deep technical expertise and relentless innovation, all aimed at unlocking new levels of efficiency and reliability.

The Complex Reality of High-Speed Design Challenges

As winding machines accelerate, multiple physical laws become far less forgiving. The very forces that deliver production gains threaten to undermine the quality, consistency, and longevity of both the machine and the product being wound. The most immediate challenge in high-speed winding design is mechanical integrity. When speeds increase, so do centrifugal forces. Components such as rotors, end-windings, and guides face greater stress, risking deformation or failure if the wrong materials, dimensions, or fastening methods are chosen. Achieving balance at high RPM is a perpetual challenge. Even minute discrepancies can generate vibration, noise, and the risk of catastrophic failure if resonance thresholds are crossed.

Thermal management is another defining hurdle. High-speed operation generates more friction, causing heat to build up in bearings, wire paths, and guiding components. If excess heat is not managed effectively, it can degrade lubricants, warp materials, and weaken insulation. This ultimately threatens the reliability, efficiency, and safety of the process. These design challenges are further compounded by the demands of continuous or long-duration operation, where “run to failure” or manual cooling are no longer viable options.

High speeds also introduce control system complexities. Rapid accelerations and decelerations require fast and accurate tension management. Layer-to-layer precision, so critical for electrical and mechanical performance in coils and stators, becomes far harder as time tolerances shrink. The whole system is less forgiving: one unstable feedback loop, one out-of-spec guide movement, and the quality of an entire high-value batch may be lost.

Innovation in Materials and Mechanical Solutions

Addressing high-speed design challenges starts with reimagining the machine’s mechanical core. Advanced materials such as carbon fibre composites or precision-machined lightweight alloys are now used to lower moving mass without sacrificing strength. This enables rotors and arms to move swiftly with less energy and lower risk of deformation. Servo-damped guide supports, and dynamically balanced shafts reduce chatter and vibration, while new high-strength bearings disperse loads and handle heat much more effectively than their predecessors.

Heat dissipation and lubrication present an opportunity for both innovation and efficiency. Today’s leading designs often integrate forced air or liquid cooling systems directly into critical points of the machine, using simulations and real-time sensors to fine-tune performance. Self-lubricating coatings and high-stability synthetic lubricants can drastically prolong component life. The efficiency dividends are clear: less downtime, fewer maintenance interventions, and reduced risk of heat-induced defects on the wound product.

Control and Automation: Staying Ahead of Complexity

At high speeds, it’s not just the hardware that needs to innovate, the brain of the machine is just as vital. Modern high-speed winding machines leverage advanced automation and real-time digital sensors to maintain consistent quality regardless of how quickly the line runs. Closed-loop tension control systems, powered by fast sensors and adaptive algorithms, ensure that wire remains perfectly taut during rapid accelerations or sudden slowdowns. Sophisticated electronic controllers can adjust traverse speed, correction timing, and wire layering in response to even the most minute process deviations.

These intelligent control systems are the product of real engineering creativity: they predict and respond to issues before they escalate, minimizing waste. Integration with ERP and MES platforms allows automated tracking of batches, instant feedback, and adaptive scheduling. This makes high-speed production both smarter and more reactive. In the most advanced plants, machine learning models “learn” the optimal process windows by analysing years of archived winding data, continuously refining machine behaviour for superior efficiency and fewer rejections.

Layering in Flexibility and Customization

Another innovation-driven trend is modular, reconfigurable design. High-speed machines increasingly need to handle diverse products, frequent changeovers, and custom winding profiles without time-consuming mechanical rework. Developers are embracing modular component frames, plug-and-play traverse heads, and user-programmable drive routines, enabling teams to dial in new geometries in minutes, not days.

This flexibility extends to digital interfaces as well. Operators interact with touchscreen dashboards presenting intuitive visualizations of wire path, tension, speed, and machine status. Automated error alerting, guided troubleshooting, and smart quality analytics empower smaller teams to oversee more machines, scaling efficiency and value across every shift.

Efficiency Gains

Efficiency is the real prize in high-speed winding design and achieving it means striking the perfect balance between investment in innovation and the practical realities of long-term operation. When machines can run faster without increasing rejection rates or mechanical risk, the manufacturer benefits from more output per labour hour, faster time to market, and greater responsiveness to demand. Efficiency also extends to resource use: intelligent wire payout, accurate spindle indexing, and low loss traversing all reduce waste and lower the cost of goods sold.

Moreover, as customers increasingly demand sustainable manufacturing, the most efficient high-speed winding machines now incorporate real-time energy monitoring. By capturing and analysing the energy profiles of each production run, operators can set processes to use less power, lower carbon intensity, and still maintain throughput. This will be a true blend of business performance and responsible manufacturing.

The Future

The landscape of high-speed winding machine design is continually evolving. With every new material, algorithm, and process refinement, the ceiling of what’s possible rises a bit higher. Innovations on the horizon include AI-driven optimizations that adjust machine parameters on the fly, collaborative robots that handle setup and maintenance, and next-generation sensors that capture process variables invisible to the human eye. Cloud-based analytics, remote monitoring, and over-the-air firmware updates will allow future designs to learn and improve continuously, long after they’ve left the factory.

These advances are not just technical milestones. They are competitive imperatives in markets where time, efficiency, and precision mean everything. The companies that succeed will not just push for speed; they will invest in the creativity and integrated thinking needed to design machines that keep performing, at any pace.

Conclusion

High-speed winding machine design is the story of modern manufacturing’s pursuit of excellence, where every challenge tackled leads to higher output, better efficiency, and new benchmarks in reliability. Whether it’s mastering mechanical tensions or investing in materials that perform under punishing conditions, the industry’s most successful leaders are those who make innovation the centrepiece of every machine. As speed becomes the new standard, the smartest solutions will blur the lines between engineering, data science, and operational agility to deliver the winding machines that global industry relies on, today and tomorrow.